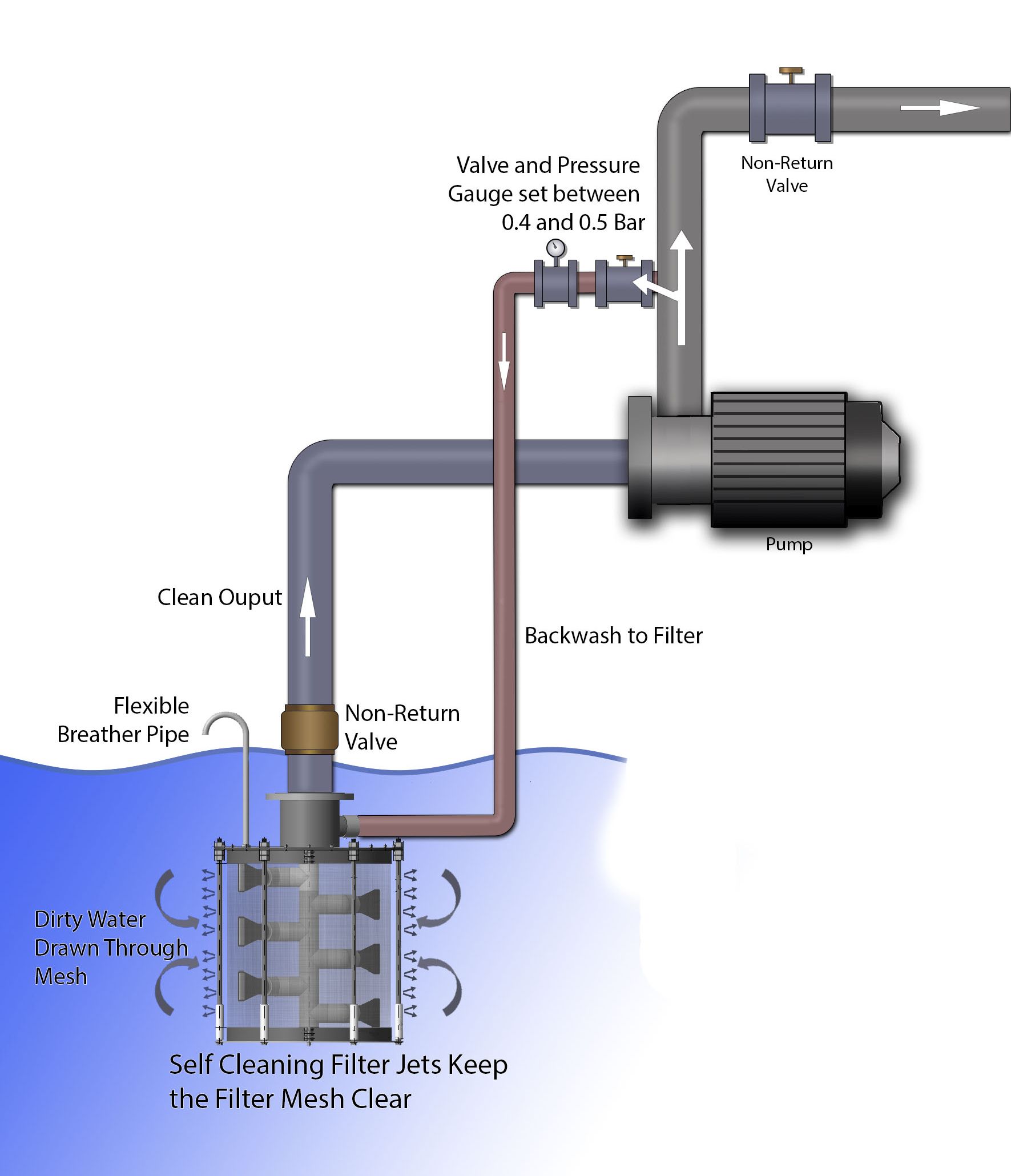

The best free-standing eel screens available

This article describes how and why Rotorflush Eel screens and Fish screens are the best eel screens available without requiring major groundwork or civil engineering. Eels screens that are low maintenance, ideal for over pumping, temporary and permanent installation, and meet EA requirements for eel screening and protection.