How Rotorflush Filterpumps™ Benefited a District Heat Pump System in Liverpool

C J Hiscock

Published

River Mersey District Heat Pump Project

The project:

As consulting engineers, KJB Water and Process Engineering Ltd had been approached to design the water intake and abstraction for a prestigious district heat pump project on the river Mersey.

KJB Water and Process and Engineering Ltd asked Rotorflush Filters on behalf of their customer to supply submersible pumps with integral self-cleaning intake screens. They wanted to pump river water for the heat pump intake system and screen the water to protect the heat pump installation from getting blocked by any debris weed or other detritus in the water.

Due to the river Mersey being tidal at abstraction points, we were told that the equipment must be suitable for use in salt water and also had to comply to Environment Agency regulations for the protection of eels.

How Rotorflush helped:

Rotorflush Filters discussed the requirements with the client - we proposed manufacturing and supplying submersible pumps with integral self-cleaning intake screens. The filter pumps would be manufactured in 316 stainless steel and fitted with galvanic anodes to combat corrosion. The intakes were to be sized to constrain the pump intake velocity to meet Eel Regulations.

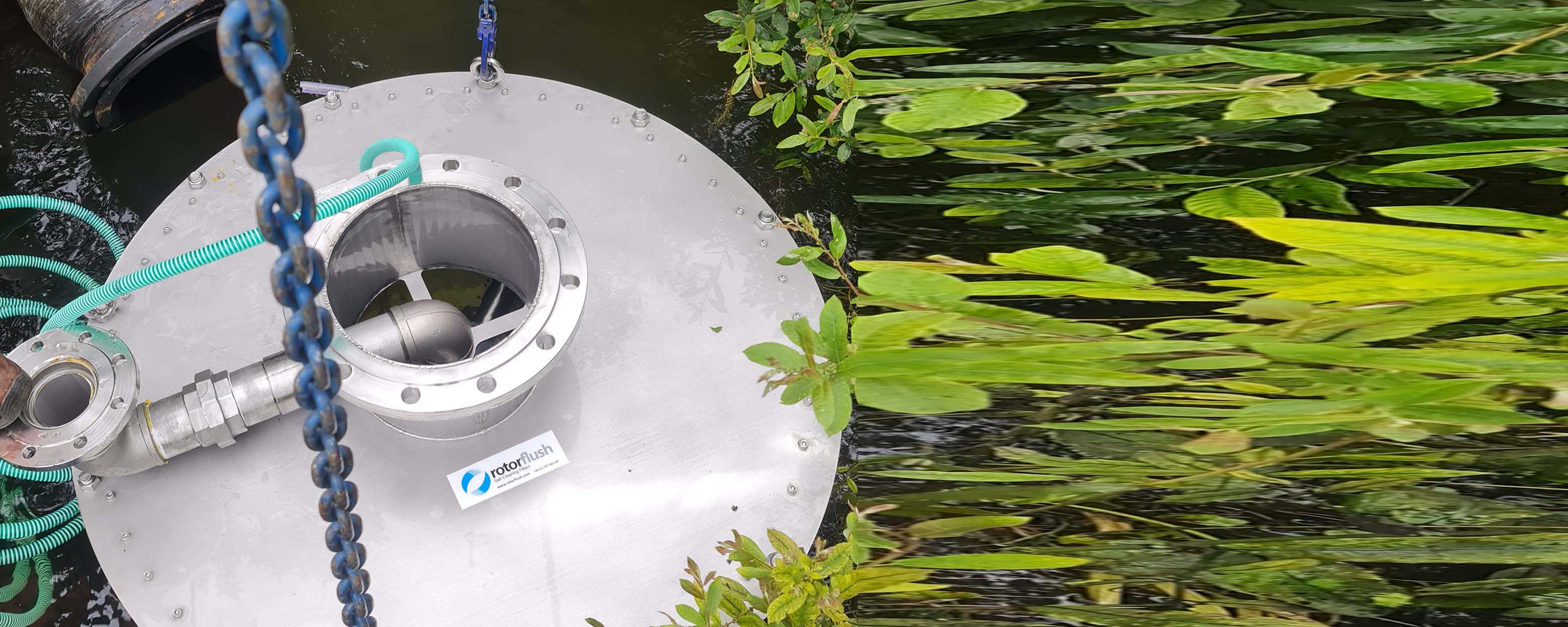

After discussions, the Rotorflush RUBI 80SFQ filterpump™ was chosen as most suitable for the client’s needs. Four units would be required, each delivering up to 54 m3 / hr to the heat pump system. These all-stainless-steel pumps were then built with a 316 stainless steel filter cage and self-cleaning eel screen with 2mm mesh.

Some bespoke features were added specifically, so the pumps could be located correctly on their underwater stand, attached to the dockside. This allows for easy lifting for maintenance and protection from large debris in the river.

Additional measures were also added to give protection against galvanic corrosion. We estimated that only a very low maintenance schedule would be required – each filter pump would need a pressure wash at site once every 12 months.

The results:

Four Rotorflush RUBI 80SFQ 211-600AR submersible filter pumps with integral 600 mm diameter, 2mm aperture mesh self-cleaning filters on the intakes were delivered to Merseyside. These were installed and the District Heating System commissioned.

- The customer now has a reliable screened supply of water through the heat pump system

- Maintenance costs are low

- The intake screens, pumps and heat exchangers don’t block thanks to the continuous backwash keeping the intake mesh clear

- The Environment Agency is pleased that eel screening is in place

- Capital works were minimised thanks to the ease of use of pumps that combined screening and pumping

- And they look great

Here at Rotorflush Filters Limited, we love working with you to find a solution that fits your requirements. We offer bespoke design and expert filtration advice for hassle-free pumping and screening in all kinds of water conditions.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.Share this insight

-

Increase productivity

-

Reduce maintenance

-

Filter to your requirements

Contact our friendly experts now

to discuss your project

Or call our team on:

01297 560229

Find out more.....

...... about how your water source heat pump system can benefit from using Rotorflush self-cleaning filters, intake screens and filter pumps.