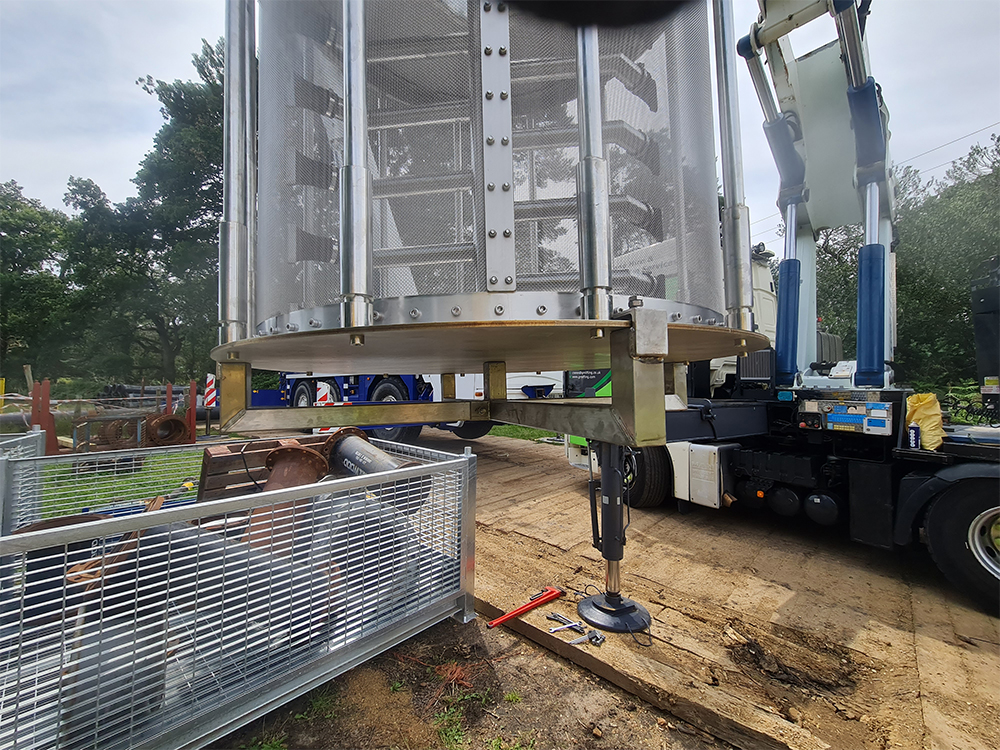

Eel Screening Intake Strainers

Rotorflush Self-cleaning Eel Screens and Eel Screening Intake Strainers are for use with dry mounted pumps. They can also be used as gravity fed intakes as long as a pump is used to supply the backwash. These large capacity pump suction hose self-cleaning filters comply with eel and fish screening regulations.