How a Stainless Steel Filter Helps You to Buy the Freshest Fruit & Veg

C J Hiscock

Published

How a Rotorflush Self-cleaning Filter Saved Laleham Farm Time and Money

What we were told:

Charlie and Claire of B.E. Bransden and Sons Ltd, farm 40 hectares in the Thames Valley, producing a range of vegetables. All Laleham Farm produce is hand harvested daily on demand, washed, cooled, packed and despatched on the day to market.

Because of this daily high demand to meet delivery deadlines, this could easily be missed if washing equipment blocked and interrupted the production process.

Charlie’s first interest in Rotorflush Filters came from a review for the RF series self-cleaning intake filters in Farmer’s weekly magazine when Rotorflush won their New Invention Competition in 1995.

He told us that the vegetable washing water accumulates in a small lagoon that feeds into settlement tanks before being pumped out again for the next round of washing, this often causes blockages with his existing equipment as the soil types in this part of the Thames flood plain range from sands, silts and some areas of particularly sticky clay.

What we did:

After speaking with Charlie, Jim Hosford at Rotorflush Filters recommended that our RF400R self-cleaning filters would be suitable as a vegetable washing filter that protects the pump and the washer nozzles from blockage.

Jim gave Charlie some installation advice for setting up the Rotorflush filter so it strains the intake from Charlie’s second settlement tank to his pumps. The unique design of the Rotorflush self-cleaning filter keeps debris away from the filter so it does not block, guaranteeing a filtered supply of water for his vegetable washing operation.

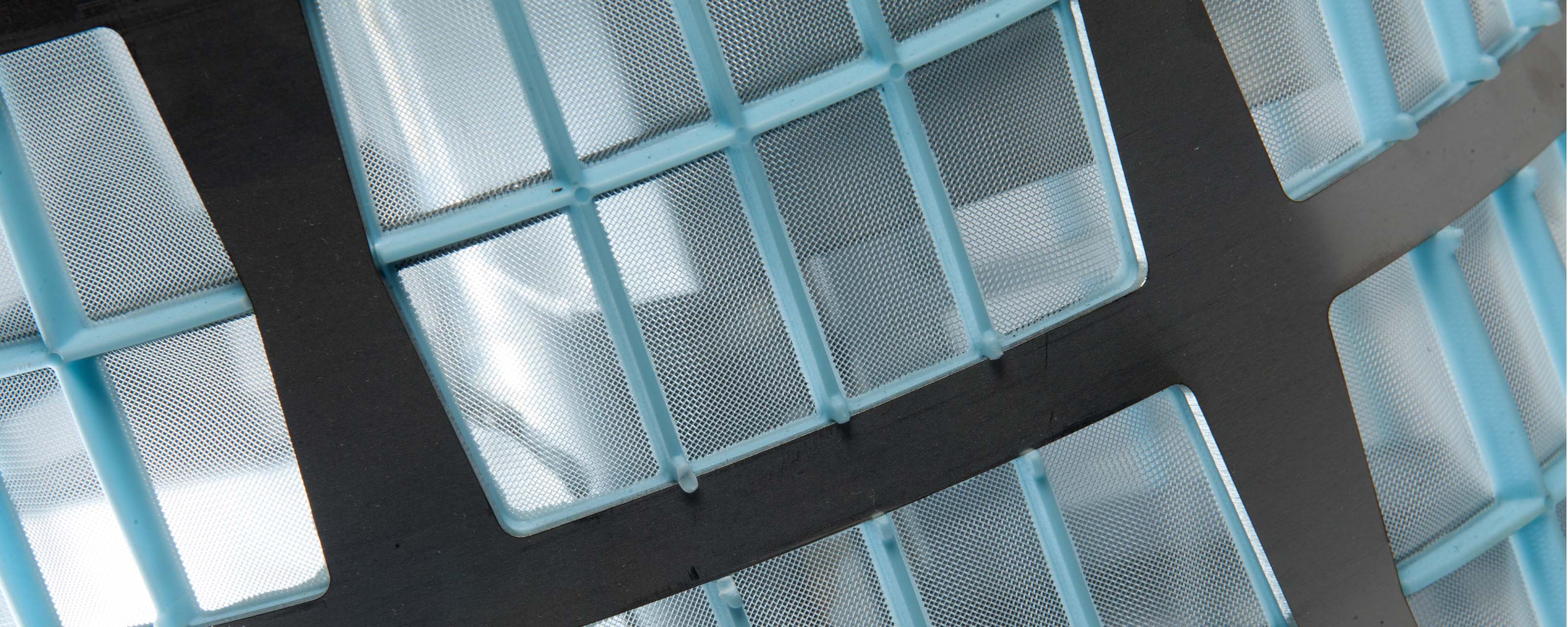

RF400 filter on site and veg washing machine it supplies

The water in the tank for the veg washing machine is drawn through the Rotorflush filter and pumped to spray bars on the machine. This water removes mud and debris from the crop, and the run-off drains back to the tank. The self-cleaning Rotorflush filter rarely clogs, and the pump and veg machine spray bars stay clear.

Periodically, the debris does need to be removed from the tank – but this can be done at less production critical times. Downtime is minimised and most of the vegetable washing water is recycled, keeping clean water costs low.

And the Outcome was:

Because the veg washing machine now suffers far less downtime, crops are washed packed, and off to market more quickly than before. As the majority of the water used is recycled, water costs are considerably lower.

Charlie first purchased from Rotorflush over 10 years ago and the filters have been in use for well over a decade due to the strong stainless-steel design. Charlie has said that the filters are “one of the most significant investments we’ve made” giving the “biggest continuing result” of any equipment.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.Share this insight

-

Increase productivity

-

Reduce maintenance

-

Filter to your requirements

Contact our friendly experts now

to discuss your project

Or call our team on:

01297 560229

Find out more.....

...... about how farmers and growers can benefit from using Rotorflush self-cleaning filters, intake screens and filter pumps.

This website uses cookies to ensure you get the best experience. Learn more