Water Pump Control Panels - What they are and what they do.

Pump Control Panels

Water Pump Control Panels: The Heart of Efficient Water Management

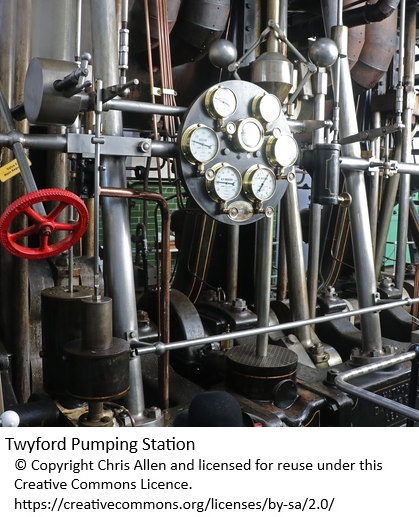

Water pump control panels are integral to the seamless operation of water and wastewater pumping systems, acting as the nerve centre that ensures efficiency, safety, and reliability across diverse applications—from residential setups to expansive industrial systems.

What they do

Pump control panels are installed to automatically control the performance of pumps as running conditions, such as depth, flow rate, power fluctuations and other factors vary.

Types of Pump Control Panels

Pump control panels come in various configurations, tailored to meet specific needs:

- Single-phase and Three-phase Panels: Depending on the scale of the pumping system and the available power supply, single-phase panels are suitable for smaller pumps, while three-phase panels are designed for larger, industrial applications.

- Control Methods: Options include Direct-on-line (DOL) for straightforward operations, Star-delta setups for reduced starting current, and Variable Frequency Drive (VFD) panels for adjustable speed operations.

- Panel Configurations: Configurations range from simplex (one pump) to duplex (two pumps), triplex (three pumps), and quad (four pumps), catering to varying operational demands.

Essential Components

The effectiveness of pump control panels is driven by several vital components:

- Main Controller Unit: Serves as the processing hub, managing sensor inputs and executing operational commands.

- Sensors and Monitoring Devices: These components gather essential data on water levels, flow rates, and pressure, providing critical feedback for optimal pump operation.

- User Interface: A user-friendly interface enables operators to easily monitor and input parameters, ensuring effective interaction with the system.

- Control and Protection Devices: This includes contactors, relays, and circuit breakers that manage the power supply and provide fault protection.

- Communication Features: Modern panels often integrate with external control systems, allowing for comprehensive management of water supply systems.

Uses and Pump Protection

Key Features and Functionality

Modern pump control panels are designed with state-of-the-art automation capabilities, enabling pumps to operate autonomously. Leveraging inputs from a variety of sensors—such as level, pressure, flow, and temperature—these panels respond dynamically to system demands. Key functionalities include:

- Protection Mechanisms: Equipped with overload and dry-run protection, these panels safeguard pump motors against potential damage. Data logging capabilities allow for monitoring of critical operational parameters, facilitating proactive maintenance when thresholds are exceeded.

Control panels protect electric pump motors that may be damaged by over heating or overloading.

- Remote Monitoring: Operators can conveniently monitor system status, receive alerts, and adjust settings from remote locations. This feature significantly enhances the management of pumps located in hard-to-access areas.

Applications Across Industries

Pump control panels are versatile and widely utilized across numerous sectors:

- Household Water Supply: Ensuring consistent water delivery and effective waste removal.

- Industrial Processes: Managing water for cooling, heating, and the transfer of liquids, including chemicals.

- Agricultural Irrigation: Automating irrigation systems to boost crop yields and conserve water resources.

- Wastewater Treatment: Efficiently controlling lift stations and treatment processes.

- Fire Safety Systems: Ensuring reliable pump operation during critical emergencies.

Selection and Maintenance

Selecting the appropriate pump control panel requires a thorough assessment of application needs, power requirements, and environmental conditions. Proper installation and routine maintenance are essential for ensuring long-term performance and reliability. This includes:

- Installation Best Practices: Ensuring proper mounting, wiring, and adherence to safety standards.

- Routine Maintenance: Conducting regular visual inspections, functional testing, and firmware updates to keep systems operating smoothly.

Comprehending the functionalities and applications of water pump control panels is vital for maintaining efficient water supply systems across various sectors. By selecting the right panel and following best practices in installation and maintenance, users can ensure the reliable, effective, and safe operation of their pumping systems.

Find out more...

about Pump Control Panels and what Rotorflush Filters have to offer to protect the filterpumps they supply.