Self-cleaning Water Filters and Strainers with Automatic Backwashing

RF100 Self-cleaning Filters

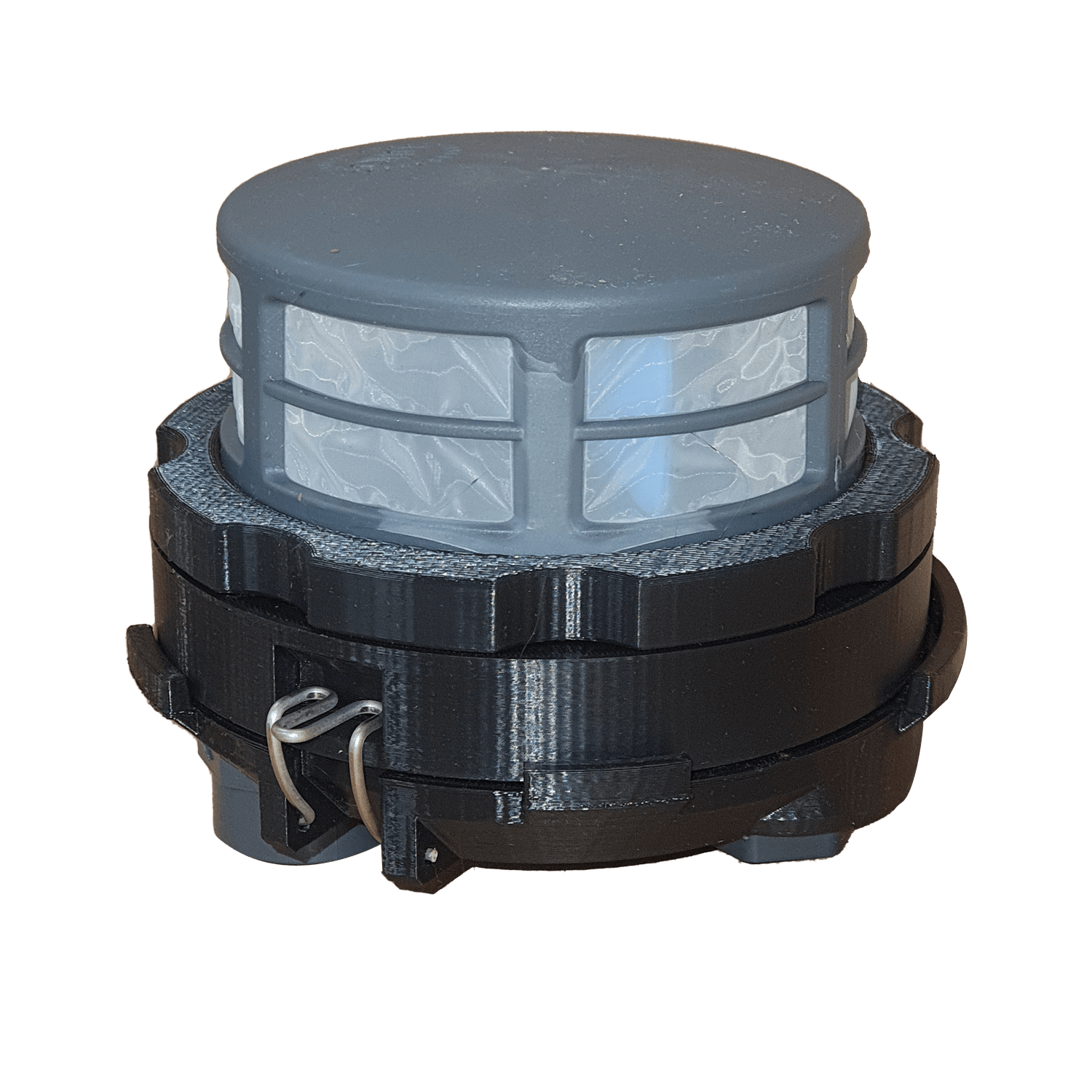

RF100 Range Self-cleaning Filters. RF100 self-cleaning filters are designed to protect dry mounted pumps and other equipment from blocking while water is being pumped. They are pump suction hose filters available with 1, 2, or 3 filter heads, for a range of flow rates up to 90 litres a minute, 24 US GPM. They can be fitted with 60, 115 or 250 micron mesh, US Mesh 230, 120 and 60.

- Filter 30 – 90 L/Min, 8 – 24 US GPM

- Screen 60, 115 or 250 Microns

- US Mesh 230, 120 and 60

Price from: £300

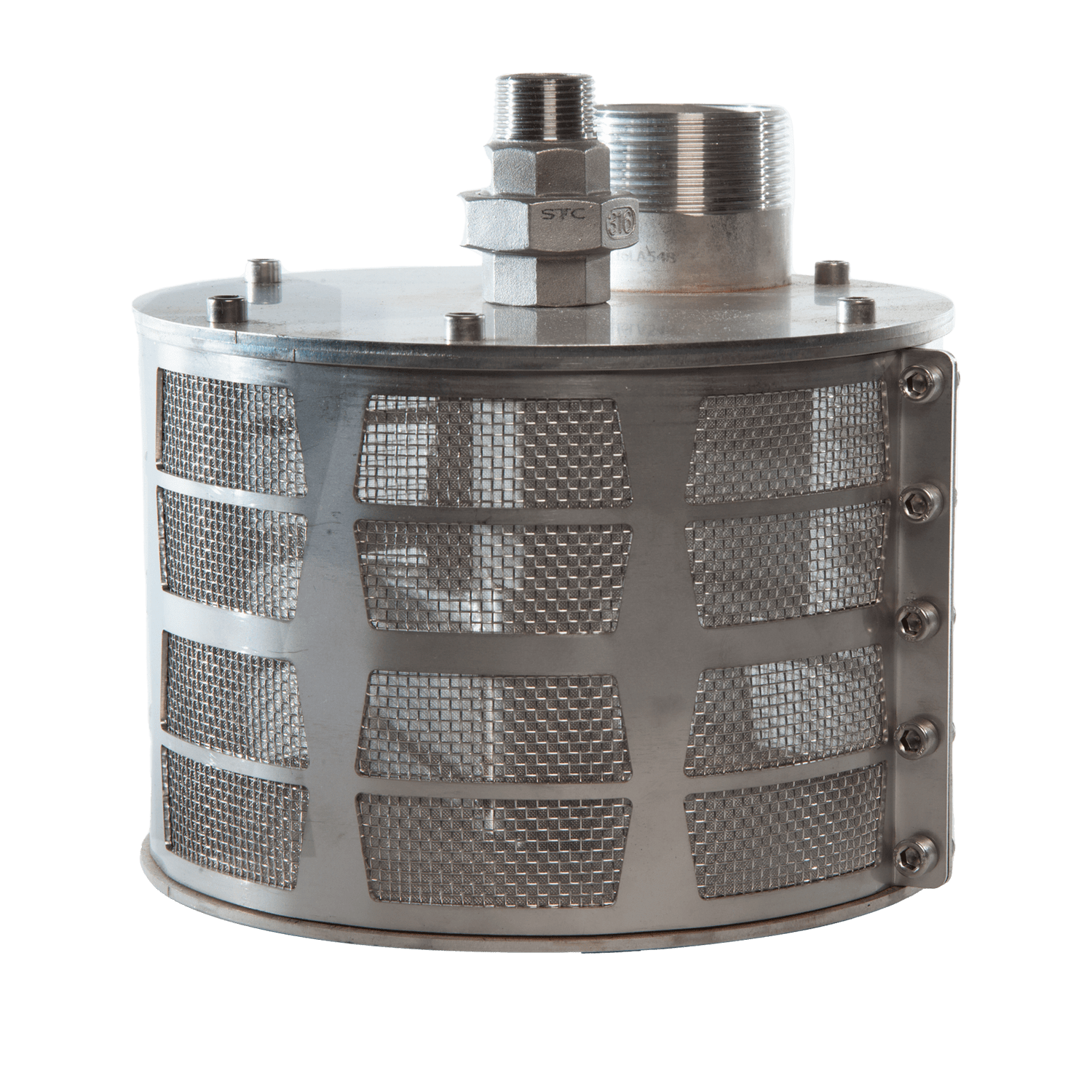

RF200 Self-cleaning Filters

RF200 Self-cleaning Filters. RF200 self-cleaning filters provide effective screening for surface mounted pump intakes. The RF200 pump suction hose filters can screen from 50 microns - 6 mm, handling up to 220 litres a minute, 58 US GPM. A continuous backwash keeps the intake screen clear.

- Screen Up to 220 L/Min, 58 US GPM

- Filter From 6 mm Down to 50 Microns

- Timed auto purge removes solids

Price from: £1,700

RF300 Self-cleaning Filters

RF300 self-cleaning filters. RF300 self-cleaning filters provide effective screening for surface mounted pump intakes. The RF200 pump suction hose filters can screen from 50 microns - 6 mm, handling up to 560 litres a minute, 148 US GPM. A continuous backwash keeps the intake screen clear.

- Screen Up to 560 L/Min, 148 US GPM

- Filter From 3 mm Down to 50 Microns

- Down to 230 US Mesh

Price from: £2,760

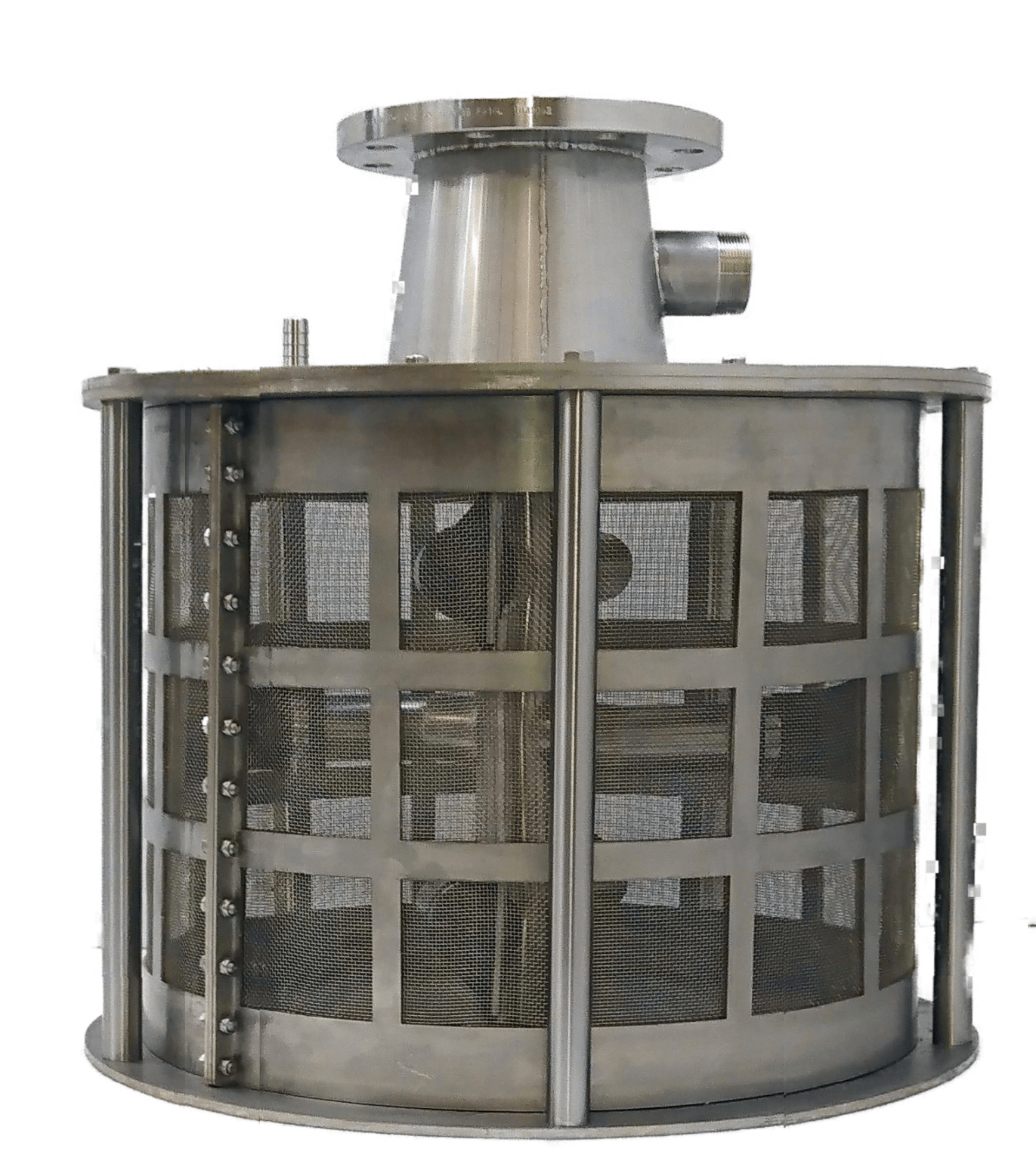

RF400 Self-cleaning Filters

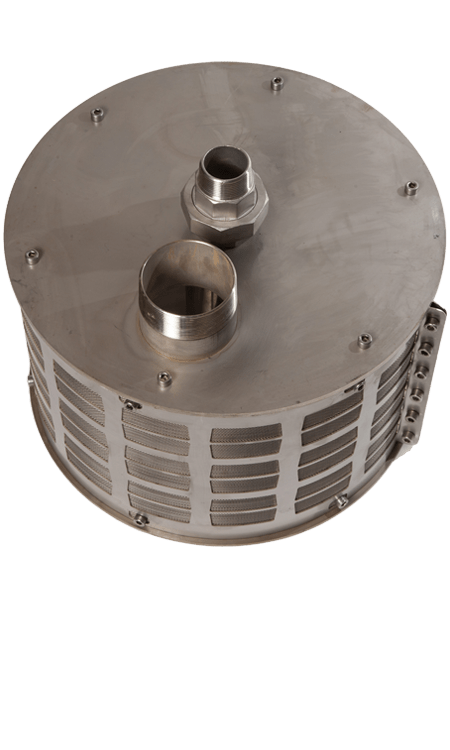

RF400 Self-cleaning Filters. Self-cleaning Industrial Water Filters and Strainers. Extremely tough, stainless steel RF400 self-cleaning basket filters are for use on the pump suction hose of surface mounted pumps. The RF400 can filter up to 1000 litres per minute, 265 US GPM, from 50 microns to 6 mm.

- Screen Up to 1000 L/Min, 265 US GPM

- Filter From 6 mm Down to 50 Microns

- US Mesh 3 Down to 230

Price from: £4,070

RF600AR Self-cleaning Strainer

RF600AR Self-cleaning Industrial Water Filters and Strainers. Our RF600 self-cleaning intake strainers are for attachment to the suction hose of surface mounted pumps. These all stainless-steel construction mechanical filters can deliver up to 376 m3/hour, 1660 US GPM

- Screen up to 376 m3 / hour, 1660 US GPM

- Filter from 6 mm down to 315 microns

- US Mesh 3 down to 50

Price from: £8,730

RF800AR Self-cleaning Strainer

RF800AR Self-cleaning Industrial Filters and Strainers. Our RF800AR self-cleaning intake strainers are for attachment to the suction hose of surface mounted pumps. These tough, industrial, all stainless-steel construction mechanical filters can deliver up to 870 m3/hour, 3830 US GPM

- Screen up to 870 m3 / hour, 3830 US GPM

- Filter from 6 mm down to 1 mm

- US Mesh equivalent 3 down to 18

Price from: £0

RF600LW Self-cleaning Filters

Self-cleaning Industrial Water Filters and Strainers. The RF600LWs are robust stainless steel self-cleaning basket filters that protect pumps and other equipment from blocking and blinding when pumping dirty water. They are fitted with 1 mm - 6 mm stainless steel mesh screens, handling up to 730 m3/hour, 3,215 US GPM.

- Screen Up to 730 m3 / Hour, 3215 US GPM

- Filter From 6 mm Down to 1 mm

Price from: £9,845

RF1000AR Self-cleaning Strainer

RF1000AR Self-cleaning Industrial Water Filters and Strainers. 1000 mm diameter self-cleaning intake strainers for attachment to the suction hose of surface mounted pumps. These tough industrial all stainless-steel construction mechanical filters can deliver up to 1,045 m3/hour, 4,600 US GPM

- Screen up to 1045 m3 / hour, 4600 US GPM

- Filter from 6 mm down to 1 mm

- US Mesh equivalent 3 down to 18

Price from: £0

RF1100AR Self-cleaning Strainer

Self-cleaning Industrial Water Filters and Strainers. RF1100AR self-cleaning intake strainers are for attachment to the suction hose of surface mounted pumps. These tough, 1100 mm diameter, industrial, all stainless-steel construction, mechanical filters can deliver up to 1,265 m3/hour, 5,570 US GPM

- Screen up to 1265 m3/hour, 5570 US GPM

- Filter from 6 mm down to 1 mm

- US Mesh equivalent 3 down to 18

Price from: £0

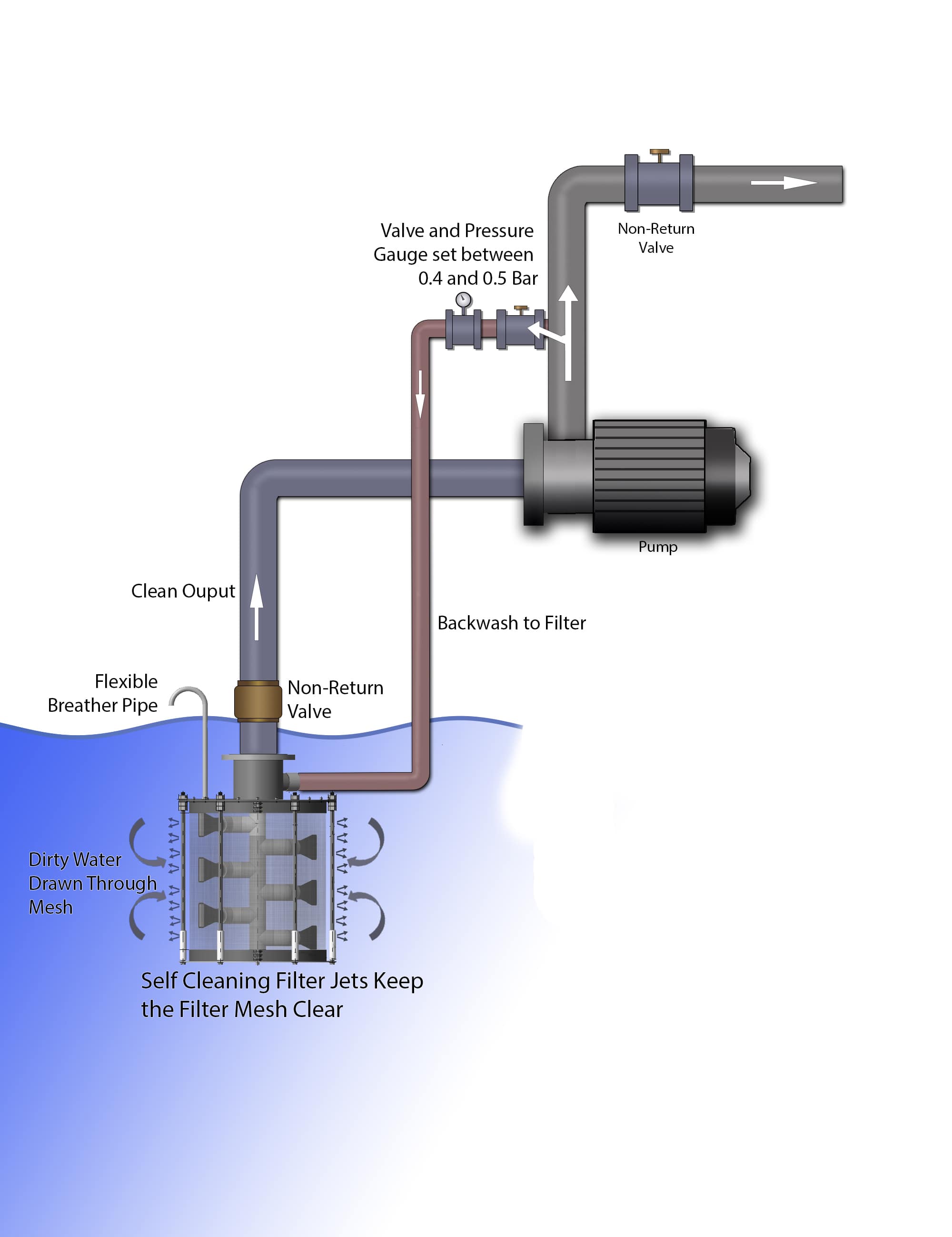

How Rotorflush Self-cleaning Backwashing Water Filters Work

How all Rotorflush suction intake self-cleaning water filters operate

Small RF100 Rotorflush self-cleaning filter on a pump suction intake fitted with 60 micron filter mesh. Shows the filter working and keeping the intake screen clear.

A self-cleaning water filter system using one of our automatic backwash self-cleaning water filters on the pump suction intake allows water to be screened or filtered as it is being pumped.

Testing an Automatic Backwashing Filter

Large Self-cleaning filters work the same way

Testing the backwash on a Rotorflush 600 mm diameter self-cleaning filter before we got the bigger workshop and test tank.

About Self-cleaning Filters and Strainers with Automatic Backwashing

About Our Self-cleaning Basket Filters with Automatic Backwash

Rotorflush Self-Cleaning Suction Intake Filters & Strainers are for use with surface mounted pumps. They are a welcome alternative to the traditional pump suction hose basket strainer. All our filters are self-cleaning automatic backwash filters – the self-cleaning mechanism prevents the filter blinding or the pump blocking.

Rotorflush filters fit to the pump suction hose of surface mounted pumps. They use the power of the water being pumped to continuously clean and clear the filter mesh. They provide an uninterrupted supply of filtered output, protecting your equipment from blockage.

Low Maintenance, Efficient Filtration

Filter from 14 m³ to over 1000 m³ / hour

Our self-cleaning suction intake filters & strainers have capacities from 14 to 1000 cubic metres per hour. Screen apertures range from 60 microns to 10 mm depending on models. They are used successfully and reliably within the water treatment industry and oil and gas sector and for eel screening in raw water abstraction.

Our pump suction hose filters and screens deliver low maintenance efficient filtration in very difficult conditions.

All our filters have an internal cleaning rotor that is powered by the pump output. By taking a ‘T’ off the output of the pump a small flow of water is directed back to the filter. This flow drives the Rotorflush internal self-cleaning rotors.

The rotors continuously backwash the mesh screen removing anything that might cause it to block.

Drive Backwash Independently of Pump Output

We also make self-cleaning suction intake filters & strainers with a built-in pump motor that drives the backwash independently of the pump output. This means that the backwash can be continuous and at a constant pressure and flow whether the main pump drawing water through the filter is demanding a high or low flow rate.

This is particularly useful if your surface pump has a variable speed motor, as variations in pump output will not affect the self-cleaning mechanism of your filter.

Rotorflush automatic backwashing filters are a robust, long-lasting alternative to the traditional basket strainer. All but the smallest filters are made from stainless steel – marine grade steel can be provided if required – and they last for years.

Eel Friendly, Compliant Solution

Rotorflush filters are gently self-cleaning low intake velocity strainers and make ideal eel screens for water abstraction. Our self-cleaning filters are Eel friendly – our products can help with your compliance with the European Commission’s Eel Recovery Plan (Council Regulation No.1100/2007) and The Eel Regulations which now apply in England and Wales.

Rotorflush Filters Ltd have designed and developed a high open area suction intake to comply with current regulations for the protection of eels.

Increasingly abstraction licences are contingent on the installation of screens and equipment to protect elvers and glass eels. These measures can be expensive and may even entail civil works to ensure the terms of the abstraction licence. Our intention was to design a suction intake filter that minimised both the approach velocity of water to a screen, and to maximise the open area of our screens to reduce the size of filters required for a given flow rate.

In addition, we believe that our cylindrical filters require less installation than other fixed structures in rivers and lakes, and that their inbuilt self-cleaning mechanism offers lower maintenance and better protection for eels.

Our Eel screens are built using tensioned 2mm woven 316 stainless steel filter mesh. This offers an exceptional open area of around 66%, which enables us to keep the overall area of the filter to a minimum. Flow rates up to 1000 m³ / hr.

Ideal for Use in These Key Areas

- Protecting irrigation equipment

- Filtration for heat exchange and cooling

- Open loop heat pump systems

- Eel Regulation compliant abstraction

- EPA Rule 316(b) compliant cooling water intakes

- Municipal fountains

- Recycling process water

- Sample filtration

- Anywhere a flow of filtered water is required.

Frequently Asked Questions About Self-cleaning Water Filters

A self cleaning filter is a robust long-lasting alternative to the traditional basket strainer. A Rotorflush self-cleaning intake filter or strainer connects to the suction pipe of a surface mounted water pump - all but the smallest filters are made from stainless steel. All our filters and strainers are self-cleaning automatic backwash filters, with in-built cleaning rotors that continuously backwash their mesh screen to prevent blocking and blinding.

Traditional basket strainers get blocked easily if the water being pumped contains any debris, weed, leaves or other particulate. The Rotorflush self-cleaning mechanism, however, uses the power of the water being pumped to continuously clean and clear the filter mesh. This means that the basket strainer can pump for much longer without being cleaned while protecting your pump and any further connected equipment from blocking.

Time and money can be saved because our strainers and filters deliver low maintenance and efficient screening in difficult water conditions.

More information can be found here

Case Study

“One of the most significant investments we've made”

C J Hiscock, Sales

Rotorflush Filters LtdHow a Rotorflush Filter Saved a Market Garden Time and Money

Read the case studyWhy Rotorflush?

UK Designed and Manufactured

Talk to our friendly team of engineers to discuss your design requirements.

- Built to your water output

- Filter down to 50 microns

- Hand built in the UK

Filtration Experts

Talk to our friendly team of engineers to discuss your design requirements.

- Industry experts for 30 years

- Over 200 products in a wide range of industries

- Installed worldwide

Worldwide Delivery and Service

Through our worldwide distribution network we offer the ability to:

- Deliver worldwide

- Give expert advice

- Have ongoing support

Talk to an Expert About Your Project

Call us now on 01297 560 229 | 8am - 5pm GMT,

or Email sales@rotorflush.com and a member of our expert, friendly team will call you back and find the self-cleaning filter or strainer for your needs.

- We work with you to identify your issues

- We can design & build a custom solution

- We can deliver our solution worldwide

Arrange a call back

Get the filter pump your project requires. Talk to our friendly team

This website uses cookies to ensure you get the best experience. Learn more