What is a Filterpump™?

Filterpumps™

What is a Filterpump™?

A Filterpump is a submersible centrifugal pump with a built-in self-cleaning suction intake filter. Correctly, it should be written as ‘Filterpump™, being the proprietary name of submersible pumps manufactured and supplied exclusively by Rotorflush Filters Ltd.

It's a made up name, erm, imaginatively invented by concatenating the words ‘filter’ and ‘pump’.

Rotorflush Filterpumps™ have a screened suction intake that is continuously and automatically backwashed to prevent clogging whenever the submersible pump is running. On our smaller submersible filterpumps (up to 1000 litres a minute) suction intakes can be screened down to 50 microns. Our large capacity filterpumps can be screened to 1 mm.

Maintenance intervals are infrequent, even with continuous running.

A Pump with a Filter isn't a Filterpump?

Not really. A submersible pump with a fine screen filter will block up very quickly unless the water being pumped is very clean. A filterpump™ therefore implies it has a self-cleaning intake to make the pump's use viable in real-world conditions.

Many pumps are fitted with foot valves with strainers, or basket strainers on their intakes. Typically, these are very coarse - 6 mm mesh on smaller pumps, anything up to 20 mm on larger pump intakes. The screen apertures are determined by the clearances through the pump impellers; this is fine for relatively hard particulate in water, but cannot prevent clogging from, for example, blanket weed, or seaweed, or …. whatever blocks your pump!

There are pump filters and possibly filter pumps, but only one self-cleaning submersible filterpump™

The Invention of the Self-cleaning Intake

The Rotorflush self-cleaning suction intake filter was invented by Jim Hosford several years ago. Dairy farmers wash out milking parlours and yards; the waste water is collected in slurry pits, lagoons, tanks and sumps, and there is always dirty water to be disposed of. Farmers struggle to dispose of the huge amounts of dirty water that dairy farming can produce.

Much of this can be pumped to irrigators and returned to land. However, pumps and irrigation equipment frequently block because the water is very dirty, pull of organic material and suspended solids that thwart the smooth running of equipment.

The Rotorflush Self-cleaning suction intake filter allows dirty water to be pumped, massively reducing the maintenance intervals required to keep conventional static intake screens clear in these conditions.

The invention and development of the Filterpump was a natural extension of Rotorflush’s application and expertise.

Watch this to see how they work

The self-cleaning technology had been tried and tested by the use of our suction intake screens across many different industrial sectors, applications and situations. Incorporating Rotorflush's highly successful self-cleaning intake into a submersible pump made perfect sense.

Now it's possible to use high-powered centrifugal submersible pumps in dirty water conditions with minimal downtime, even though impeller clearances may be small.

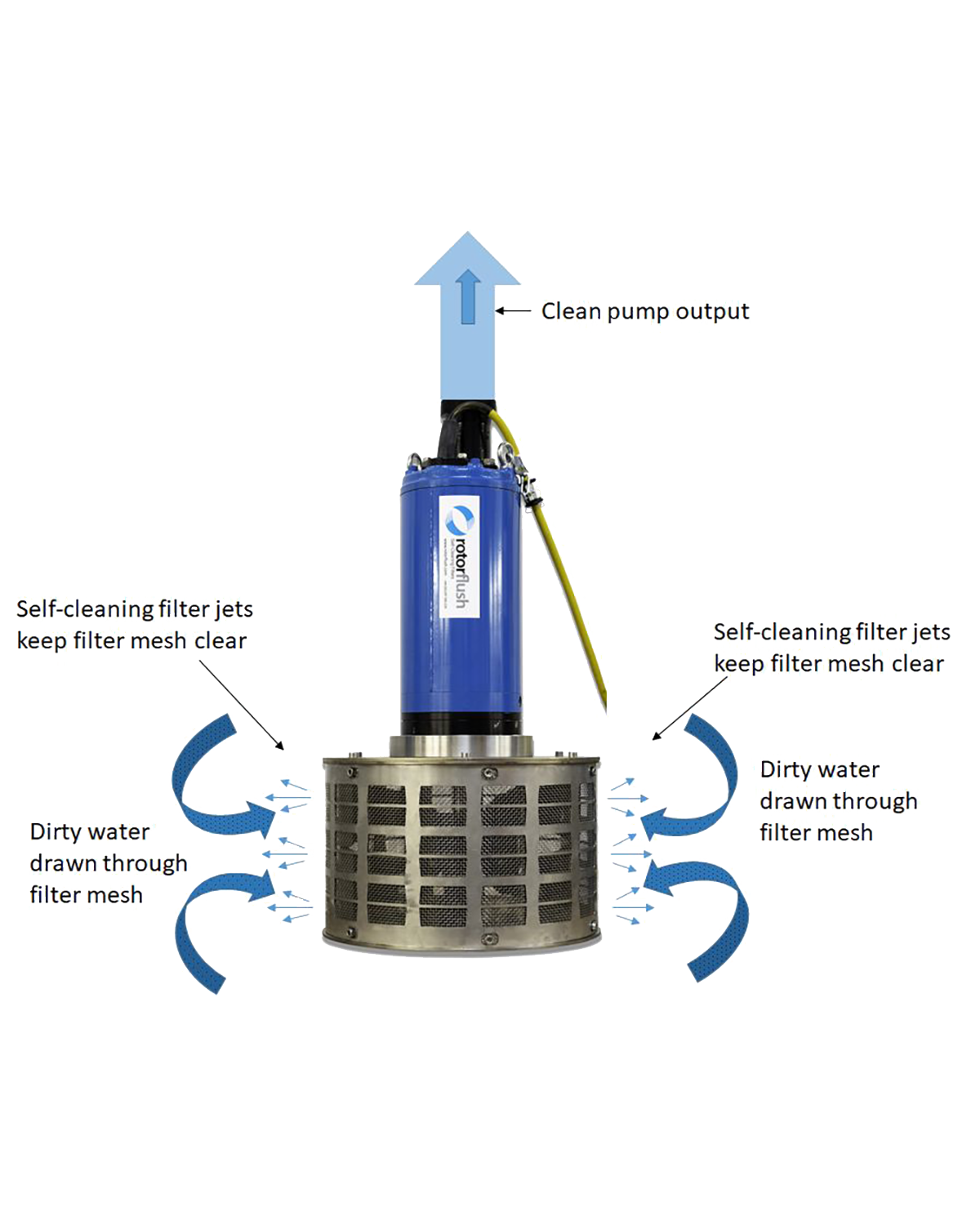

The self-cleaning intakes work by providing a continuous backwashing to the intake mesh. In essence: the pump sucks a high volume of water in through the mesh at a relatively low velocity.

The Filterpump™ provides a higher velocity, lower volume backwash back through the mesh, dislodging any debris that could potentially block the screen.

How Filterpumps™ work.

The actions of drawing water and clearing the intake screen are simultaneous, effective, and the flow of water is not interrupted.

The result is that screens block only very infrequently, saving time and money on that would otherwise be spent unblocking screens, pumps or other equipment being supplied by the pump.

Rotorflush Filterpumps™ are used for raw water irrigation, for pumping final effluent as wash water in waste water treatment works, to provide wash water for eel screens, and to protect heat pumps and cooling systems. The filterpumps are environmentally and fish and eel friendly, and have been purchased by the Environment Agency, the RSPB and the Wildfowl and Wetlands Trust.

Do I need a Filterpump™?

Good question! If you intend to use a submersible pump for any reason, you'll need to consider the following.

Water quality

Water quality can be very variable, particularly raw water, and this can affect your water supply. While, for example, lake water may look crystal clear, at some times during the year the opposite may be true. Seasonal blooms of algae and weed can easily choke a pump.

Similarly, extreme weather events causing flooding may churn up the lake bed or drag soil, sand and debris off the land into the water.

Application

A filterpump provides water screening at source as water is pumped. Water may contain very little debris, but consider what other equipment may be affected. The pump may be able to tolerate a certain level of particulate, but this may not be true of the drips and nozzles of a connected irrigation system, or wash water spray bars.

System Resilience

Consider your entire system from water source to point of delivery. You need to be aware of the narrowest apertures, critical equipment, and how accessible components - including the filterpump - are for maintenance.

Advice

Here at Rotorflush Filters we are happy to discuss any requirements you may have and give you the benefit of our many years of experience screening pumping and filtering all kinds of water.

What is a Filterpump™? Find out more

Get in touch to find out more about how Rotorflush Filterpumps™ and self-cleaning filtration products can benefit you.

Contact the Rotorflush team for a discussion with our knowledgeable and friendly staff.