Screening at Raw Water Intakes

Screening Raw Water Intake

What is a Raw Water Intake?

A Raw Water Intake is a structure or system designed to divert and collect raw water – that is untreated water found naturally in the environment - from rivers, lakes, groundwater or the sea. A Raw Water Intake is used to supply water to facilities for various uses including drinking water supply, industrial use, agriculture uses or as cooling water.

As well as a structure or method of collecting the water a Raw Water Intake may additionally have a storage area to hold water before it is treated and used, a pumping station or similar to move the water if other than by gravity, and some initial means of screening the water ahead of any further required treatment or filtration.

Raw water has not undergone any treatment to remove impurities and contaminants that it usually contains. Raw water is rarely used without first undergoing some screening or treatment to reduce or remove any debris, particulate or other contaminants that may be in the water.

Types of Raw Water Intake and Screens

Raw Water Intake designs can take many forms, these are the most common:

Submerged Intakes

These are entirely underwater and are designed to minimize the intake of surface debris and sediment

River and Lake Intakes - Bar Screens

These intakes are specifically designed for withdrawing water from rivers and lakes, often incorporating screens and other mechanisms to remove debris, such as bar screens or travelling screens. Bar screens block the ingress of larger debris, travelling screens remove debris. Both need maintenance to keep them clear, ideal where the water quality is good.

Rivers and Lakes - Travelling Screens

Travelling screens like these, waiting to be installed, lift debris from the intake water.

Water Intake Towers

Water intake towers are either ‘wet’ or ‘dry’.

A dry intake tower has no water inside it other than in the intake pipes.

A wet intake tower contains water up to the level of water in the source (sea, lake, reservoir etc).

The Links below are to two excellent essays in Engineering Notes (https://www.engineeringenotes.com/)

Types of Intakes | Water Collection | Water Engineering

Intakes: Design, Types and Selection | Water Collection | Water Engineering

Why Screen at Raw Water Intakes?

Water taken out of the environment for whatever purpose will usually need to be treated before use. Intake screening is the first process, and more often than not is in fact a pre-filtration ahead of other processes to further clean up the water.

What needs to be done to the water will depend on the water quality, the intended use(s) for the water, and whether there is a need to protect wildlife. The reasons for screening will vary with application, but these are the main concerns:

- Maintaining Water Quality. Screening is used to ensure a reliable and efficient water supply, drawing the best quality water available from the water source

- Protecting Equipment. Screening removes large debris that could damage or clog pumps, pipes, irrigation equipment and other machinery in industrial processes

- Protection of Aquatic Life. Screening is often required to minimize the impact on fish and other aquatic life.

Typical applications for a Raw Water Intake are:

- Supplying Water Treatment Plants. Raw water is the source of all our potable water, and undergoes various treatment processes, such as filtration, disinfection, and chemical treatment, to remove impurities and make it safe for drinking. Raw water intake screening is the first stage of these processes.

- Providing Water for Industrial Use. Many industries require large quantities of water for cooling, manufacturing, cleaning, and other processes. Raw water intakes deliver this water to industrial plants and factories for further treatments if required and use depending on the specific needs of their processes.

- Agricultural Use. Raw water is used for irrigation, livestock watering and produce washing. While the water does not particularly need to be treated, screening removes debris that might otherwise clog and block pipework, spray bars, hoses, nozzles and other agricultural equipment.

- Cooling water for various industrial processes requiring temperature regulation, data centres, District Heating systems and more, Wash water for cleaning and rinsing in industrial settings.

Intake Maintenance - Self-cleaning Screens

Keeping the Water Flowing

The requirement for screen maintenance will be driven by the purpose for screening, water quality and location. For the most part, coarse bar screens with a flow past the screen will only need very infrequent maintenance, even in poor water conditions.

Fine screen water intakes (i.e. screens with apertures of 3 mm or less) are much more likely to block and clog in raw water. Fine screens are often fitted to protect downstream equipment, for example drip irrigators or spray bay nozzles, and even to extend the maintenance intervals of finer filtration systems after the screen. Finer screens may also be required for regulatory reasons, especially for eel and fish protection.

Finer mesh screens will either need a strict and frequent maintenance regime to ensure that the water intake runs freely, or the screens will need to incorporate a cleaning mechanism to increase the intervals between manual maintenance.

Types of Self-cleaning Intake Screen

Various methods and designs of self-cleaning intake screen are out there, some work better than others depending on how and where they are deployed. Costs and capital investment will depend on whether the intake screens are incorporated into permanent structures, or whether they are for temporary use. Three such screen types are:

Traveling Screen

Traveling or elevator intake screens rotate to lift debris out of the intake stream. These operate continuously and are usually fixed structures built into an intake. Spray bars remove debris from the screens.

Wedge Wire Screen

Wedge wire screens, often designed as a wedge wire cylindrical intake underwater are static screens. These can be self-cleaning if connected to compressed air supply. Periodically, or in response to a differential pressure indicating the screen is blinding, a sustained blast of compressed into the cylindrical mesh is used to force debris off the wedge wire screen.

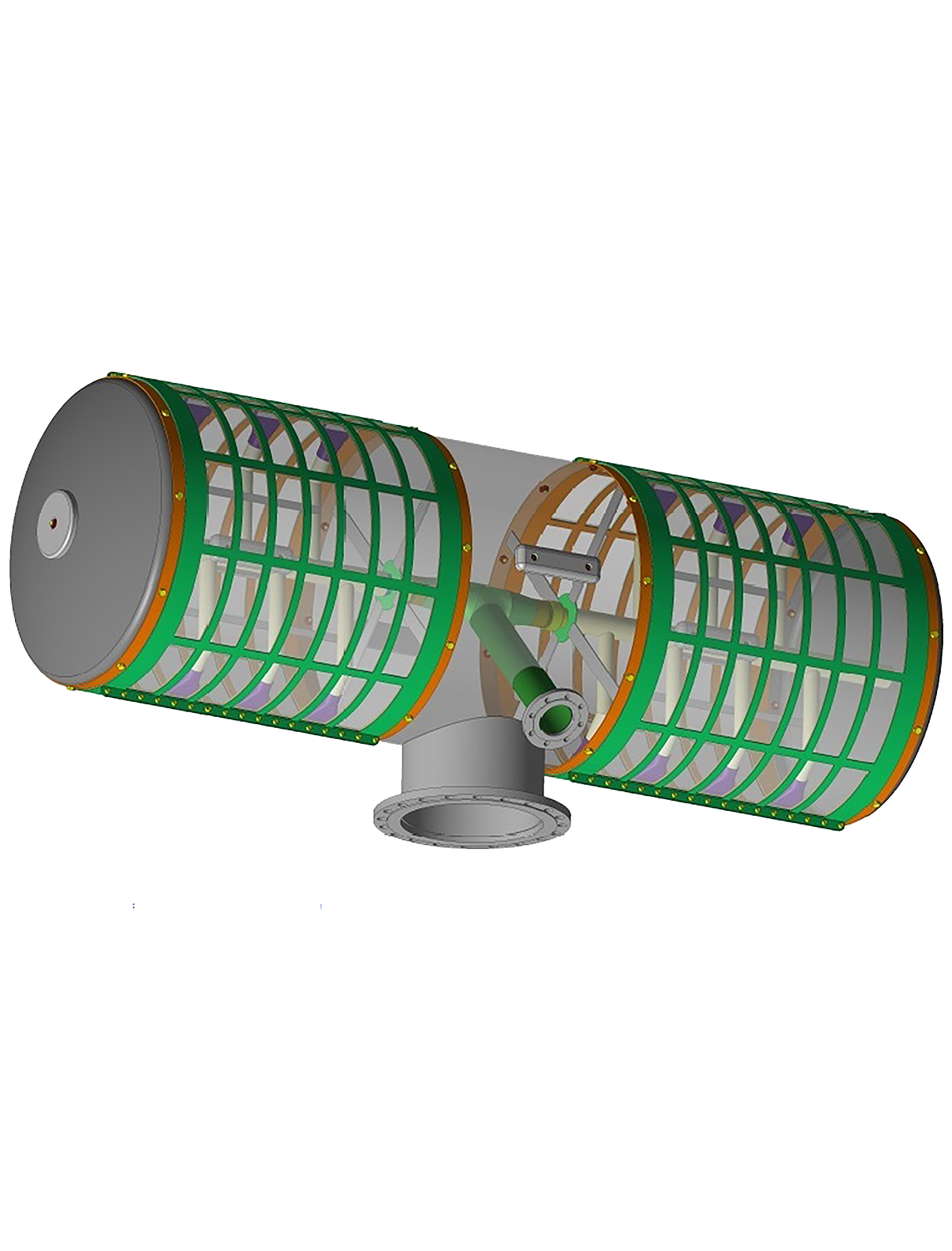

Rotorflush Self-cleaning Intake Screen

Rotorflush self-cleaning strainers are for both temporary and permanent installation, either for a gravity fed or pumped intake. These strainers benefit from a high open area mesh, a low intake velocity and continuously self-clean as water is drawn through them.

Find out more....

Get in touch to find out more about screening at raw water intakes using Rotorflush Filterpumps™ and Self-cleaning Intake Screens.

Contact the Rotorflush team for a discussion with our knowledgeable and friendly staff.