Learn More

Custom-built Self-cleaning Filters

Rotorflush Filters can Custom Build Self-cleaning Filters and Strainers to Suit Your Application or Project Requirements.

By combining our award-winning self-cleaning filter technology with sound engineering and modular design principles Rotorflush Filters Ltd can design, manufacture and deliver purpose built self-cleaning industrial water intake strainers for your application or project.

We can scale our filters to meet required flow rates and vary the configuration to fit particular locations, installations and specific industrial applications. We can build strainers and screens to be EA Eel Regulation compliant and to meet EPA Rule 316(b) intake requirements. All our products are thoroughly tested and CE marked.

We combine our expert knowledge of filtration and experience in precision engineering to meet our customers needs. Rotorflush Filters Ltd. can design, manufacture and deliver a purpose built self-cleaning industrial water intake strainer to the size and specification you require.

Your design can be realised in our CAD studio and delivered to you from our precision engineering workshop and test facilities in beautiful Charmouth on the UK’s Jurassic Coast.

All our custom-built self-cleaning filters and strainers can be made Eel Friendly to meet current EU and UK regulations for Eel Recovery and to meet EPA Rule 316(b) intake velocities for the protection of marine and aquatic life.

Frequently Asked Questions

Our filters and filterpumps are modular; the self-cleaning mechanism is common to all products. This means we can scale our products to meet required flow rates.

Rotorflush offers various mesh sizes, different outlet sizes to suit, and can customise the height and diameter of intakes as required.

We can, to some extent, vary the configuration of our products to fit particular locations, installations and specific industrial applications. There may be depth or space constraints that would benefit from a particular intake configuration, or a need to screen to certain size. Materials too can be varied – we offer 316 stainless steel and super duplex construction for some product sets.

We can produce filterpumps to meet our customer's flow rates, intake velocities and screening needs.

We combine our expert knowledge of filtration and experience in precision engineering to meet our customers' needs. Rotorflush Filters can design, manufacture and deliver a purpose-built self-cleaning filter to the size and specification you require. All our filters incorporate Rotorflush’s unique self-cleaning mechanism to prevent the filter blocking.

Not every submersible pump is suitable to be turned into a filterpump.

When we manufacture a filterpump we re-engineer the pump to have an additional impeller to provide the wash water to the screen without sacrificing the output of the pump.

Re-engineering a pump can often invalidate its warranty. Therefore, we would highly recommend that you opt for one of our Filterpumps that come with their own 1-year warranty.

If however you have a particular pump that you would like to be made into a filterpump please contact us to discuss.

Recent Commissions

Rotorflush has been commissioned to design, manufacture and supply self-cleaning suction intakes for vertical pumps abstracting seawater for cooling from the Gulf of Mexico.

Our self-cleaning intakes allow 2 mm aperture mesh screening at an EPA Rule 316(b) compliant intake velocity while protecting the screen and pump from blockage.

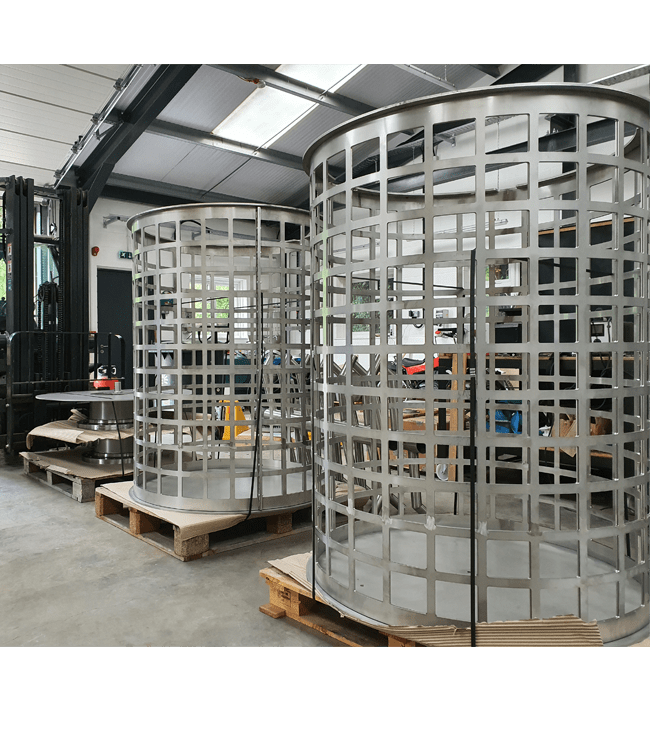

RF1100-1100AR strainers redy to be shipped to Mexico

The sizes and shapes of our screens can be varied. A customer wanted filters for dockside firefighting pumps at a refinery.

The strainer needed to have domed ends for strength, but the available depth was minimal. To save space, yet meet the flow rate needed, we designed and built strainers with convex rather than concave ends.

A leading supplier of pumps wanted to ensure that their hire Flygt submersible pumps could comply with Eel regulations in the UK.

The submersible pumps needed 2 mm screening at a low intake velocity for the pump flow rate. Rotorflush worked with the pump supplier to produce a bespoke design filterpump incorporating their Flygt pumps and our unique self-cleaning suction intake, providing an eel friendly large capacity submersible pump available to hire.

Custom Built Flygt Pump with Self-cleaning Intake

We provided a UK water company with 25 strainers for eel screening at raw water intakes. The self-cleaning strainers were fitted with 2 mm mesh screens and adaptions for use with a unique lifting system.

These strainers screen millions of gallons of water for treatment ahead of the potable water supply.

This website uses cookies to ensure you get the best experience. Learn more