Learn More

Browse Products

Omnia Filterpumps™

Rotorflush Omnia Filterpumps™. Submersible pumps with built-in pump suction self-cleaning filters. Single phase low head filter pumps - up to 220 litres a minute, 45 US GPM. Ideal for sampling and small open loop heat pump systems.

- Maximum Output 220 L/ Min, 45 US GPM

- Maximum Head 11 m, 25 ft

Price from: £2,260

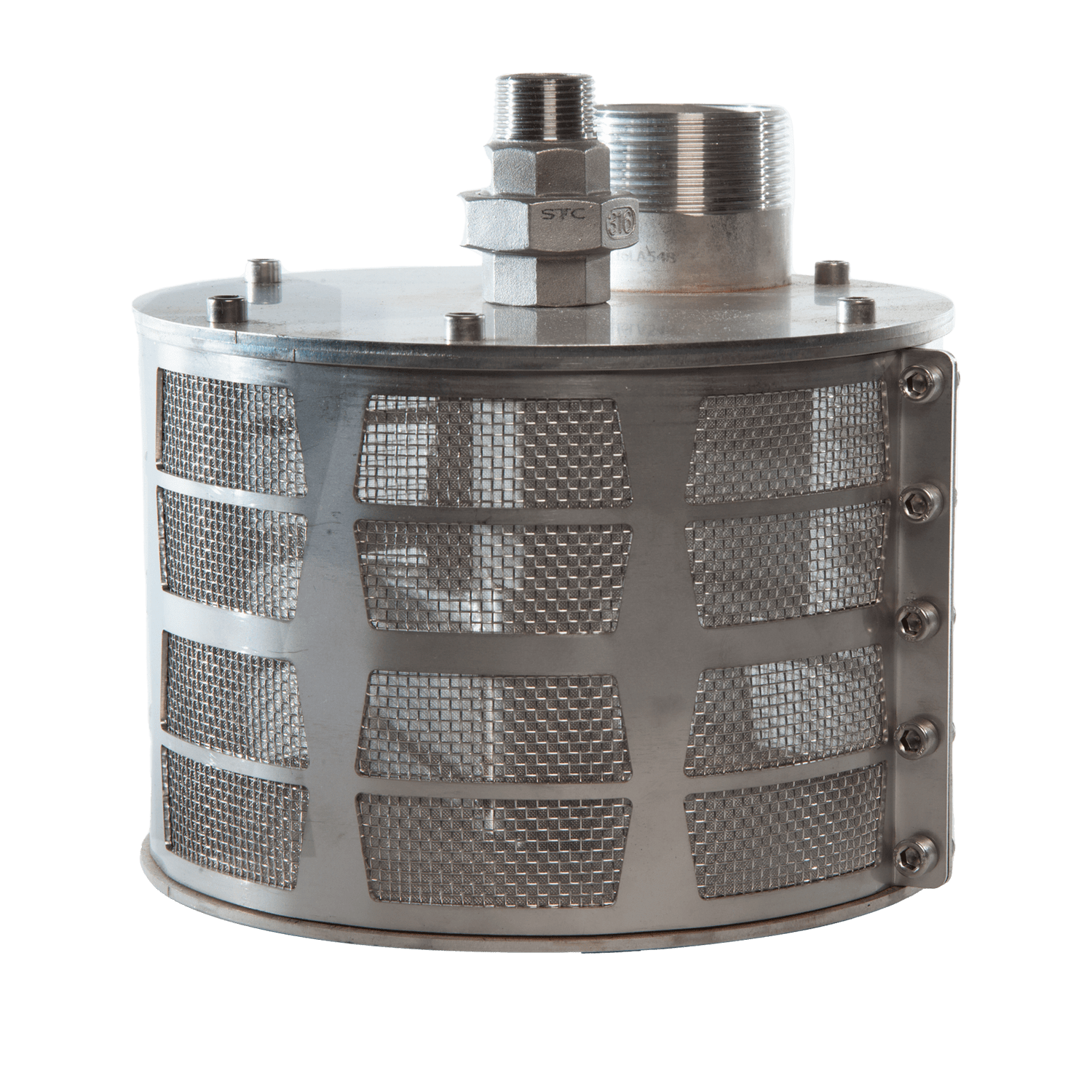

RF200 Self-cleaning Filters

RF200 Self-cleaning Filters. RF200 self-cleaning filters provide effective screening for surface mounted pump intakes. The RF200 pump suction hose filters can screen from 50 microns - 6 mm, handling up to 220 litres a minute, 58 US GPM. A continuous backwash keeps the intake screen clear.

- Screen Up to 220 L/Min, 58 US GPM

- Filter From 6 mm Down to 50 Microns

- Timed auto purge removes solids

Price from: £1,700

Beryl Filterpumps™

Rotorflush Beryl Filterpumps™. 50 Hz low head submersible filter pump with an integral self-cleaning filter on the pump suction intake. Robustly built with wear-resistant rubber and ductile iron for durability, up to 420 litres / min, max head of 17.5 m.

- Maximum output - 420 l p m, 110 US GPM

- Maximum head - 17.5 m, 57.4 ft

Price from: £0

RF600AR Self-cleaning Strainer

RF600AR Self-cleaning Industrial Water Filters and Strainers. Our RF600 self-cleaning intake strainers are for attachment to the suction hose of surface mounted pumps. These all stainless-steel construction mechanical filters can deliver up to 376 m3/hour, 1660 US GPM

- Screen up to 376 m3 / hour, 1660 US GPM

- Filter from 6 mm down to 315 microns

- US Mesh 3 down to 50

Price from: £8,730

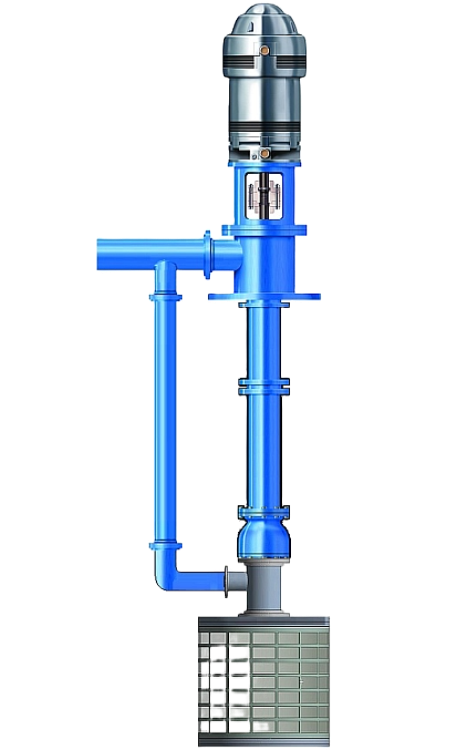

Cobalt 400 Filterpumps™

Rotorflush Cobalt 400 Filter Pumps. Industrial low to medium pressure submersible pumps with an integral self-cleaning filter on the suction intake. These robust filter pumps offer high volume pumping and screening - up to 75 m3 / hr, 330 US GPM.

- Maximum Output - 60 m3 / hr, 265 US GPM

- Maximum Head - 19 m, 62 ft

Price from: £8,980

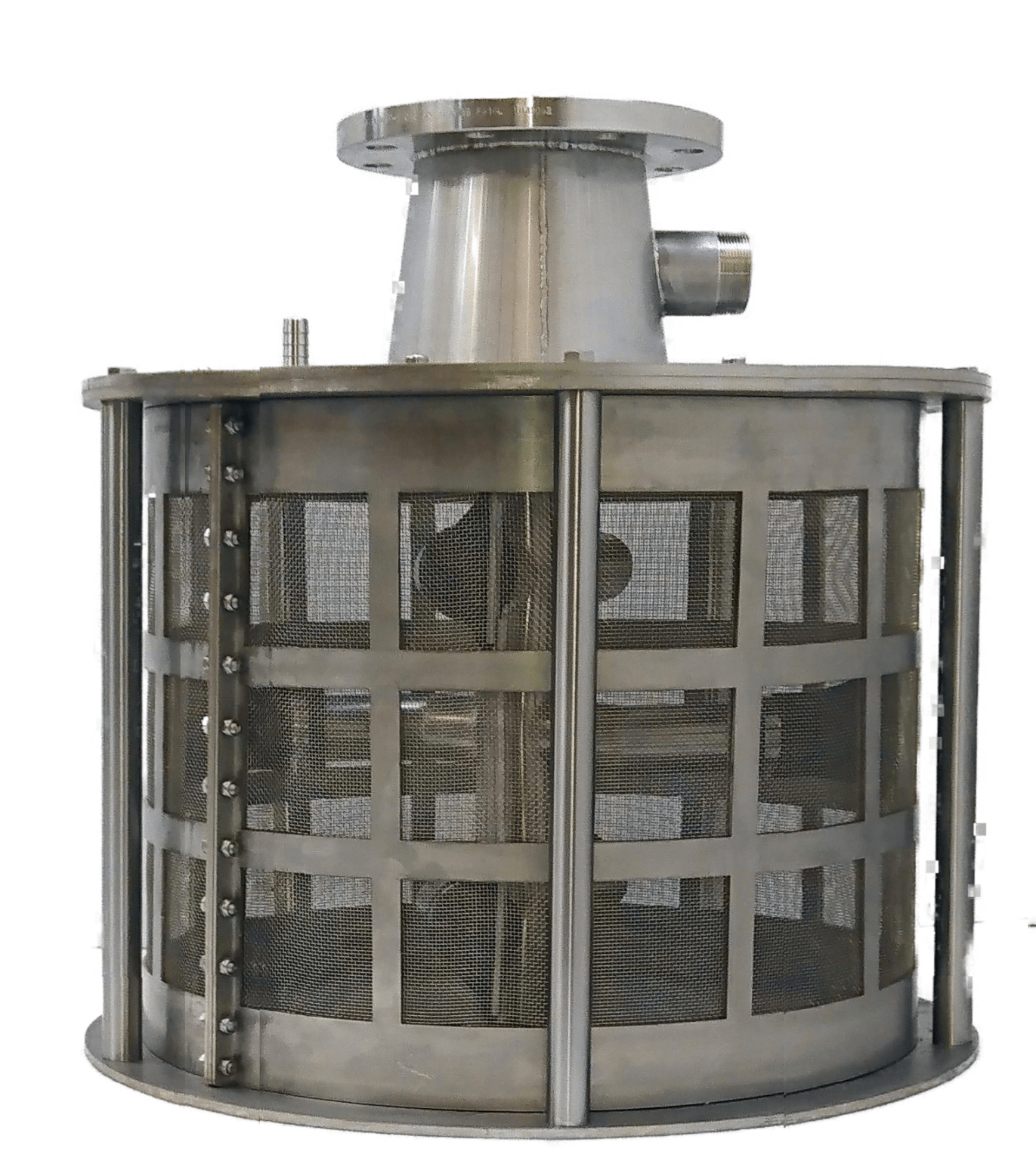

RF800AR Self-cleaning Strainer

RF800AR Self-cleaning Industrial Filters and Strainers. Our RF800AR self-cleaning intake strainers are for attachment to the suction hose of surface mounted pumps. These tough, industrial, all stainless-steel construction mechanical filters can deliver up to 870 m3/hour, 3830 US GPM

- Screen up to 870 m3 / hour, 3830 US GPM

- Filter from 6 mm down to 1 mm

- US Mesh equivalent 3 down to 18

Price from: £0

Jasper Filterpumps™

Rotorflush Jasper Filterpumps™. Industrial submersible filter pumps with self-cleaning filter intakes. Low and medium head stainless steel pumps with a maximum output of 1000 l/min and a maximum head of 35 metres. Corrosion resistant 316 stainless steel versions are also available for use in brackish water, seawater and harsh industrial conditions.

- Maximum Output – 1000 L/Min

- Maximum Head 35 m

Price from: £8,580

RF1000AR Self-cleaning Strainer

RF1000AR Self-cleaning Industrial Water Filters and Strainers. 1000 mm diameter self-cleaning intake strainers for attachment to the suction hose of surface mounted pumps. These tough industrial all stainless-steel construction mechanical filters can deliver up to 1,045 m3/hour, 4,600 US GPM

- Screen up to 1045 m3 / hour, 4600 US GPM

- Filter from 6 mm down to 1 mm

- US Mesh equivalent 3 down to 18

Price from: £0

RF1100AR Self-cleaning Strainer

Self-cleaning Industrial Water Filters and Strainers. RF1100AR self-cleaning intake strainers are for attachment to the suction hose of surface mounted pumps. These tough, 1100 mm diameter, industrial, all stainless-steel construction, mechanical filters can deliver up to 1,265 m3/hour, 5,570 US GPM

- Screen up to 1265 m3/hour, 5570 US GPM

- Filter from 6 mm down to 1 mm

- US Mesh equivalent 3 down to 18

Price from: £0

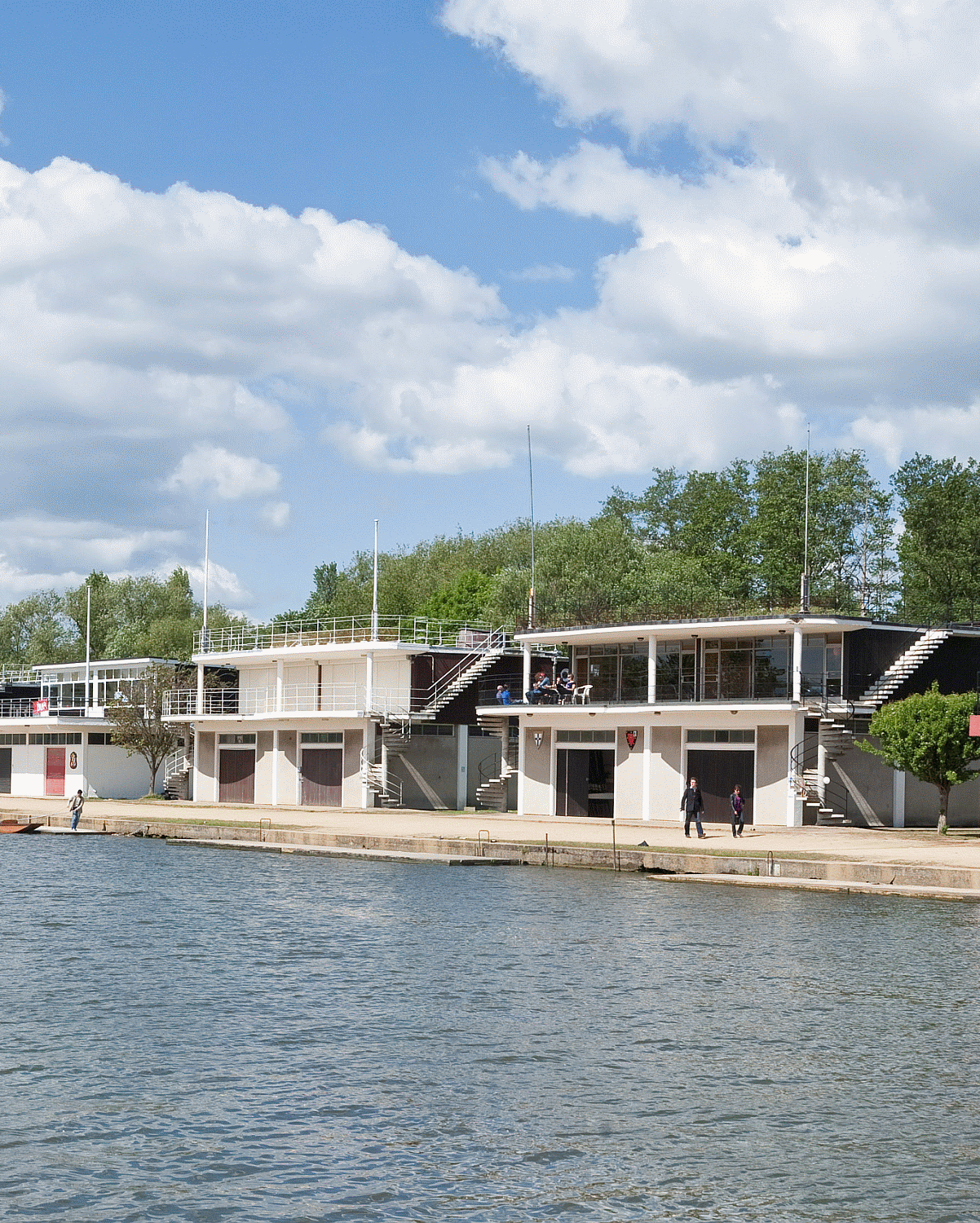

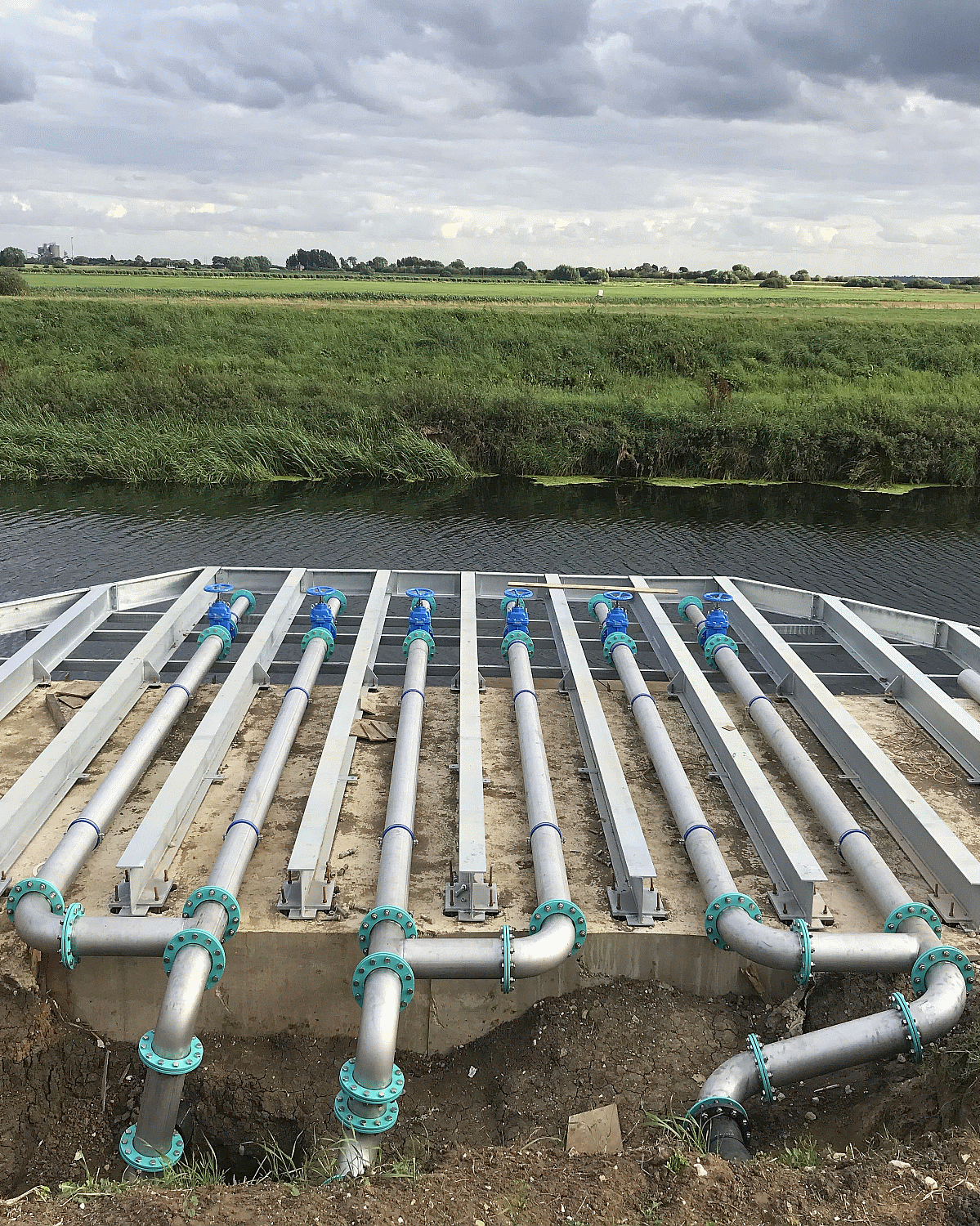

In the drive to reduce carbon emissions, we've seen an increase in enquiries for the use of our products with open loop water source heat pump systems, and cooling water generally.

A Rotorflush submersible filter pump screening and pumping water directly from the water source prevents debris and particulate entering your heat-pump system.

How Rotorflush Filterpumps™ Protect Heat Exchangers

Rotorflush submersible filter pumps with integral self-cleaning suction intakes enable water to be screened and pumped simultaneously. This makes them the ideal option for supplying water for cooling systems and water source heat pump installations.

Open Loop Water Source Heat Pumps

Heat pump systems work by recovering heat (solar energy) stored naturally in the air, ground or water and using this recovered heat as a source of energy to heat homes and businesses. An open loop water source heat pump system uses open water, such as a lake, river, pond or the sea as its heat source. The water passes through heat pumps to transfer its heat before being returned to the water source.

Heat pump installers and manufacturers are recognizing the benefits of Rotorflush submersible pumps for filtering and pumping water through plate heat exchanges.

The filter pump's self-cleaning intake prevents weed and other debris from entering the system. This protects the narrow apertures within the heat exchanger and reduces the need for secondary filtration.

They offer a low maintenance solution to supplying open loop water source heat pumps where the water quality may be variable.

Rotorflush Self-cleaning Intakes for Cooling Water

There is massive and increasing demand for cooling water - both for industrial and domestic applications. Smart buildings are using heat exchange to save energy costs and reduce their environmental impact.

Cooling Water

A typical example would be the use of river water to cool servers. Raw water is abstracted and pumped through a heat exchange system before being discharged back to the river. Screening the water on intake will prevent debris, weed and aquatic life from blocking heat exchange equipment.

Rotorflush Filters Ltd offer self-cleaning intake screens for use with dry mounted pumps and vertical turbine pumps. We also make and supply submersible filter pumps with integral self-cleaning suction intakes. These both enable screening and pumping of water at source.

In the UK and Europe, regulations are in place for Eel and Fish protection that limit cooling water intake velocity and the size of screen mesh that can be used. Similar protections are in force in North America within EPA Rule 316(b) for cooling water intakes.

Rotorflush self-cleaning intakes are designed for low intake velocity, 1 - 2 mm mesh screening and low maintenance.

Why Opt for a Open Loop Water Source Heat Pump System?

John Barker-Brown, special projects' manager at British heat pump manufacturer Kensa Heat Pumps says:

“Using water as your energy source has a number of advantages when compared to air or ground source:

The heat transfer rate from water is far higher than that in the ground or air. The flow/circulation of the water source provides constant energy replacement.

The use of a water source removes the need to dig large trenches, often reducing the cost of installation compared to a ground source.

The return temperature to the heat pump is usually higher than either the ground or winter average air, increasing the CoP (coefficient of performance) of the heat pump.”

Fortunately for those living or working near an accessible water source, Rotorflush self-cleaning intake basket strainers and submersible filter pumps with built-in self-cleaning intake screens make drawing and using water for heat exchange easier and more feasible.

Why Are Open Loop Systems Becoming More Popular?

The UK and other countries are seeking to reduce their output of greenhouse gases by the increased use of renewable energy and low energy systems

In the UK the Renewable Heat Incentive (the RHI) provides an incentive for installing heat pump systems. RHI is a payment system for the generation of heat from renewable energy sources introduced in the United Kingdom on 28 November 2011. It applies to industrial and domestic installations.

Water has a greater capacity to retain heat than air, and it is better at transferring heat in plate heat exchangers. Air systems are at their least efficient on the coldest days when they are most needed, whereas river and lake water is a more efficient store for heat, retaining energy from the sun that has built up in the preceding months.

The Dept for Energy and Climate Change (DECC) recognises that there is huge scope for open loop water source heat pump systems within the UK and has published a map identifying the 40 urban areas that can immediately benefit from the adoption of these systems.

The use of Rotorflush filter pumps has increased the feasibility of low maintenance open loop water source heat pump installations.

Domestic Heat Pump Filtration

I contacted the team at Rotorflush Filters Ltd as I was looking for a submersible pump that would work well alongside my open loop heat pump systems.

Joel Gustafsson

Joel Gustafsson ConsultingSimple, reliable filtration was a prerequisite to it working, and the self-cleaning filter pump suited the application perfectly.

The sales and technical team were happy to discuss my requirements and recommended the Omnia O35012-16MA fitted with a 50 micron mesh. All communication was efficient, and I was updated at each step of my order, the team worked hard to expedite delivery and made a custom tweak to the cable to assist with the application.

As a consequence, the installation was easy, and I am very pleased with how it is working, thank you to all at Rotorflush Filters.

Frequently Asked Questions

All of our self-cleaning intake screens are specified to suit required flow rates, for instance filter pumps are recommended based on the flow rate and pressure your system needs and intake strainers and screens are specified according to the maximum flow through that is required.

Consideration should be given to what mesh size you need - top tip, go for the largest mesh size you can to minimise maintenance. This will be determined by the smallest aperture the water you are drawing needs to go through; check with your heat pump manufacturer.

If you need advice or more information, please get in touch.

We need to know how much water your heat pump system needs - the maximum flow rate will determine the size of intake and pump required.

We also need to know the operating pressure. To accurately specify this we need to know:

- The static head - i.e. how high the water needs to be lifted

- The pressure drop through the heat exchanger / heat pump from the manufacturer

- The length of the pipe run from the water source and back to the water source

- The pipe diameter and ideally the number of bends / elbows in the pipe work.

This will allow us to calculate the overall pressure drop through your system and specify the correct filter pump.

Not every submersible pump is suitable to be turned into a Rotorflush Filterpump™.

When we manufacture a filter pump, we re-engineer the pump to have an additional impeller to provide the wash water to the screen without sacrificing the output of the pump.

Re-engineering a pump can often invalidate its warranty. Therefore, we would highly recommend that you opt for one of our Filterpumps™ that come with their own 1-year warranty.

If however, you have a particular pump that you would like to be made into a filter pump, please contact us to discuss.

Increasingly, the Environment Agency makes taking steps to protect eels a condition of abstraction licences in England and Wales. These environmental regulations may have a bearing on the type of filter pump or strainer you need.

Our Products can be sized to account for Eel Regulations or EPA rule 316(b) if applicable, so that intake velocity and mesh size meet regulatory requirements for the flow rate you require. We are happy to advise, please get in touch.

Yes – because our products pump and filter directly from a dirty water source, there is less need for additional expensive in-line filtration. All our products have built-in self-cleaning backwashes that prevent intake screens from blocking, keep pumps clear and protect other connected equipment.

This reduces maintenance, minimises downtime and can extend the life of pumps. In addition, our products are easy to install directly in your water source, often avoiding the need for expensive building and engineering work.

Why Rotorflush?

UK Designed and Manufactured

Talk to our friendly team of engineers to discuss your design requirements.

- Built to your water output

- Filter down to 3 microns

- Hand built in the UK

Leading Water Filter Experts

Talk to our friendly team of engineers to discuss your design requirements.

- Industry experts for 20 years

- 200 installations

- Installed worldwide

Worldwide Delivery and Service

Through our worldwide distribution network, we offer the ability to:

- Deliver filter pumps worldwide

- Help service your filter pump

- Repair broken filter pumps

Talk to an Expert About Your Project

Call us now on 01297 560 229 | 8am - 5pm GMT,

or Email sales@rotorflush.com and a member of our expert, friendly team will call you back and and find the self-cleaning filter, strainer or filter pump to suit your needs.

- We work with you to identify your issues

- We can design & build a custom solution

- We can deliver our solution worldwide

Arrange a call back

Get the Filter Pump or Self-cleaning Filter Your Project Requires. Talk to Our Friendly Team

This website uses cookies to ensure you get the best experience. Learn more