"I would also like to say, what an absolute pleasure it is dealing with you. Rarely do I come across people that provide levels of service you are providing. Thank you."

Kevin S.

"BTW, The filters we recently had from you for the Avon project were excellent, we pulled in excess of 750l/s through them, with a back pressure of approximately 0.75 bar, they performed really well even with floating grasses and weeds in the water course"

Nick

South West Water

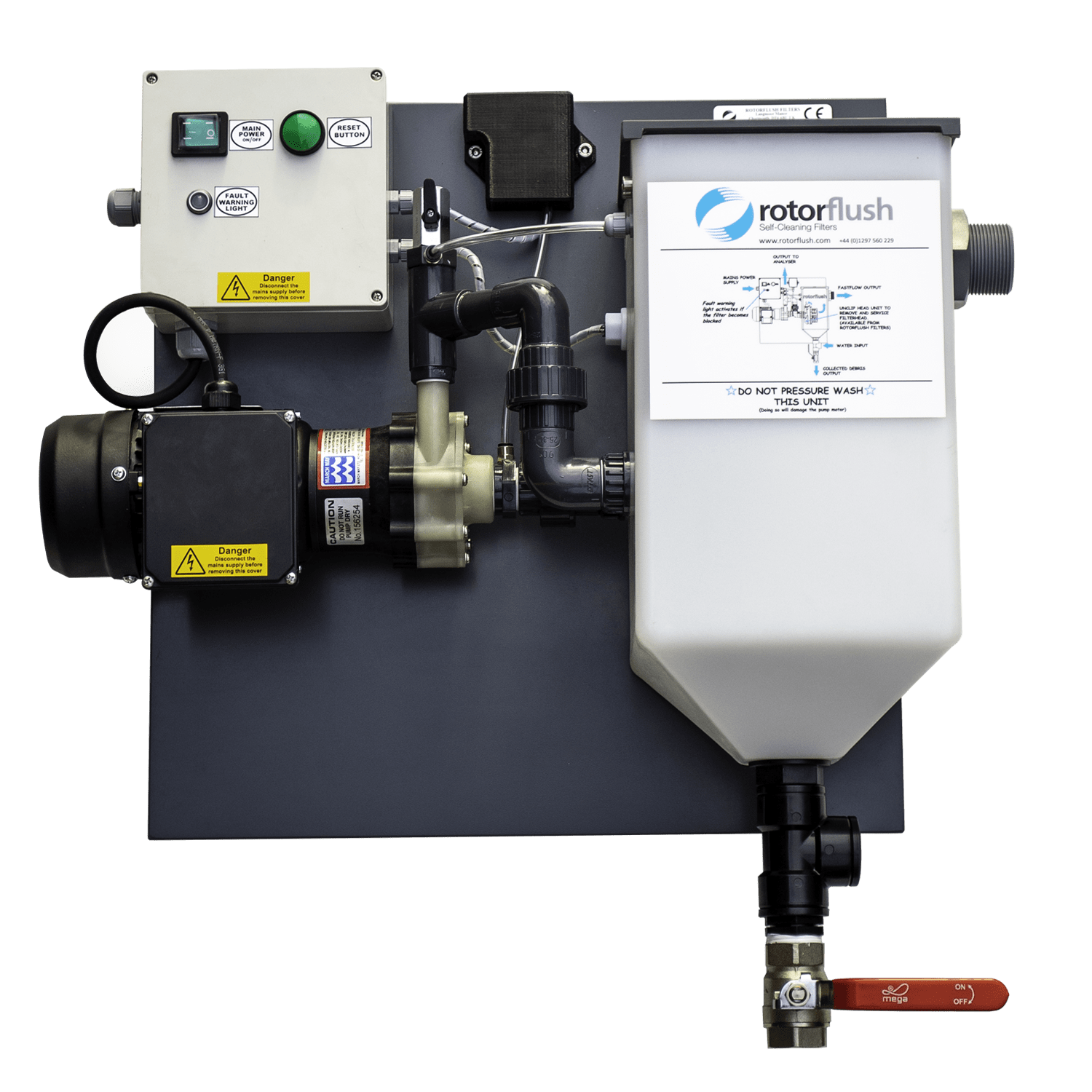

"I thought you might be interested to know that your pump continues to work beautifully, and we have had the ABB ACS580 VFD+dU/dT output filter hooked up to it for several months now, and everything seems to be working magnificently. It’s really very impressive how little there is trapped in the mesh after hours and hours of use!"

Daniel

"Firstly thank you for delivering on time as we had a very tight and strict deadline. The system has so far worked very well. I am also pleased so far with the limited amount of water loss needed for the back wash cleaning. Overall my initial view is one of approval and subject to dealing with algae etc later in the season I will be very satisfied and purchase more in the future if the need arises"

Roger

"There are many aspects in your company that I appreciate. If I had to summarize, I would say : "So far, so good. Therefore, please endeavour to keep on your track of excellent service and products!""

Laurent, our French distributor at Sonitec France says...

"Continuous improvement and innovation. The care taken during manufacturing is visible. The quality of the products is therefore sound and consistent."

"Pleasant relation with the whole staff, friendly and professional."

"We have just installed your triplex. I am beyond happy – thank you so much from me and the Newts. Having inadvertently killed so many newts and tadpoles etc with other pond pump filters with I feel quite evangelical about this"

Tiki

"Just wanted to let you know that we received our order Friday afternoon and we are very impressed with the service. Thank you again and looking forward to doing more business with you"

Sylvia

Entec Green

This website uses cookies to ensure you get the best experience. Learn more