Rotorflush Filters Limited is an Award Winning UK Engineering Company. We produce a unique range of self-cleaning pump intake filters, suction strainers and on-line analyser filter systems. We produce standard and bespoke self-cleaning filters and strainers for pump suction intakes. Rotorflush also produce a range of submersible filter-pumps with built-in self-cleaning pump intake filters. All our products incorporate our patented and unique Rotorflush self-cleaning filter technology.

About us

Rotorflush engineers are experts in liquid / solids separation.

We offer practical, real world solutions to the problems customers face when pumping dirty water. We have advised and helped our many satisfied customers worldwide. Furthermore, we help our customers manage their dirty water filtration problems while keeping down-time and maintenance to a minimum. We help them to keep pumps unblocked, keep wash-water flowing, keep their fountains looking good and their irrigation equipment unblocked and running. Our self-cleaning intakes are a cost-effective means of eel and fish screening, reducing the need for permanent installs or extensive civil engineering.

We are very happy to share our knowledge and expertise with you. Let us know your pumping and filtration issues.

Have a look at our new Product Catalogue. We are very happy to share our knowledge and expertise with you. Let us help with your pumping and filtration requirements.

About Rotorflush and How We Work

Reputation and Quality

Rotorflush filters are large enough to provide excellent customer service and small enough to provide a personal response to your enquiries. Therefore, much of our business comes from recommendation and referrals as customers tell their friends and colleagues about us. Consequently, we are establishing a reputation for reliability and efficiency in the self-cleaning water filter market place.

Browse our product range to find out more.

Qualified and Experienced

Our team is qualified and experienced in suction side water filtration. Above all, Rotorflush Filters Ltd are experts in liquid / solids separation. We offer practical, real world solutions to the problems customers face when pumping dirty water. We have advised and helped our many satisfied customers worldwide and are very happy to share our knowledge and expertise with you. Let us know your pumping and filtration issues. If you wish to know more about what we do or about us, Rotorflush Filters are happy to take your calls and emails.

Please call 01297 560229 or email sales@rotorflush.com

All our filtration products are designed and manufactured in the UK. We care about quality and test every model before delivery so that they are robust and reliable. Our filters and filter pumps are used by the water industry, food manufacturing sector, oil and gas industry, agriculture and many other industries throughout the world.

What We Make and Do

We produce a unique range of self-cleaning pump intake filters, suction strainers and on-line analyser filter systems.

Rotorflush Filters Ltd produce standard and bespoke self-cleaning filters and strainers for pump suction intakes. We also produce a range of submersible filter-pumps with built-in self-cleaning pump intake filters. All our products incorporate our patented and unique Rotorflush self-cleaning filter technology.

As a Company we help our customers manage their dirty water filtration problems. For example, we help them to keep pumps unblocked, keep their fountains looking good and their irrigation equipment unblocked and running.

Getting the Right Product

Rotorflush Filters Limited – experts in the filtration of suspended solids from water. Our filtration knowledge pages describe differing self-cleaning filtration products. Learn how they work and why you may need them.

Our products are being used on farms, in water treatment works, in laundries, and for sampling for water analysis. Our filter pumps supply water source heat pumps and are used in many more industries where there is a need to filter dirty water. And, if you are abstracting raw water that needs to be screened for fish or eel protection, our products will help you comply with regulations.

Our experience and advice can help you decide which is the best filter to use. Here you will find useful information about liquid solids separation, self-cleaning filter pumps, suction strainers and filters. There is also information on the most appropriate filtration for different applications and varying levels of dirty water.

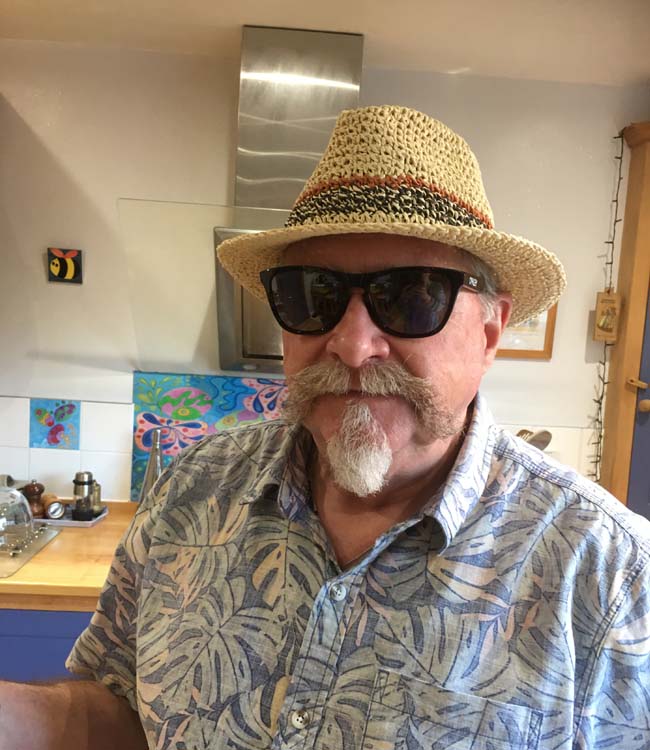

Jim Hosford - Managing Director

Jim is our Managing Director and inventor of the patented and unique Rotorflush self-cleaning suction intake filter.

Formerly a dairy farmer fed up with continually unblocking pumps, pump intakes and irrigators, his invention now forms the basis of all our high quality industrial filtration equipment.

Nick Hosford

Nick is responsible for R&D and Fabrication for the Company

He is equally happy producing 3D prints of new components or welding parts to prototype and realise our new products.

Christopher Hiscock

Christopher handles Sales and Marketing for Rotorflush Filters Ltd

He is usually your first contact when enquiring about our products and is happy to discuss how our products can help with your filtration requirements

Naomi Way

Naomi is our highly efficient Engineer / Office Manager and often the first point of contact for all things Rotorflush

Chloe Peavoy

Chloe joined us as a new administrator, as we're getting bigger we realised that we need another pair of helping hands, Chloe was crazy enough to accept the challenge of working at Rotorflush!

How Can We Help?

Rotorflush manufacture, design, engineer, service and repair to offer you complete solutions from filterpump conception to implementation to operation.

This website uses cookies to ensure you get the best experience. Learn more